Tool setter market situation and trends in China

Tool setter market situation and trends in China There is a strong demand for the tool setting in the Chinese market, According to statistics, China

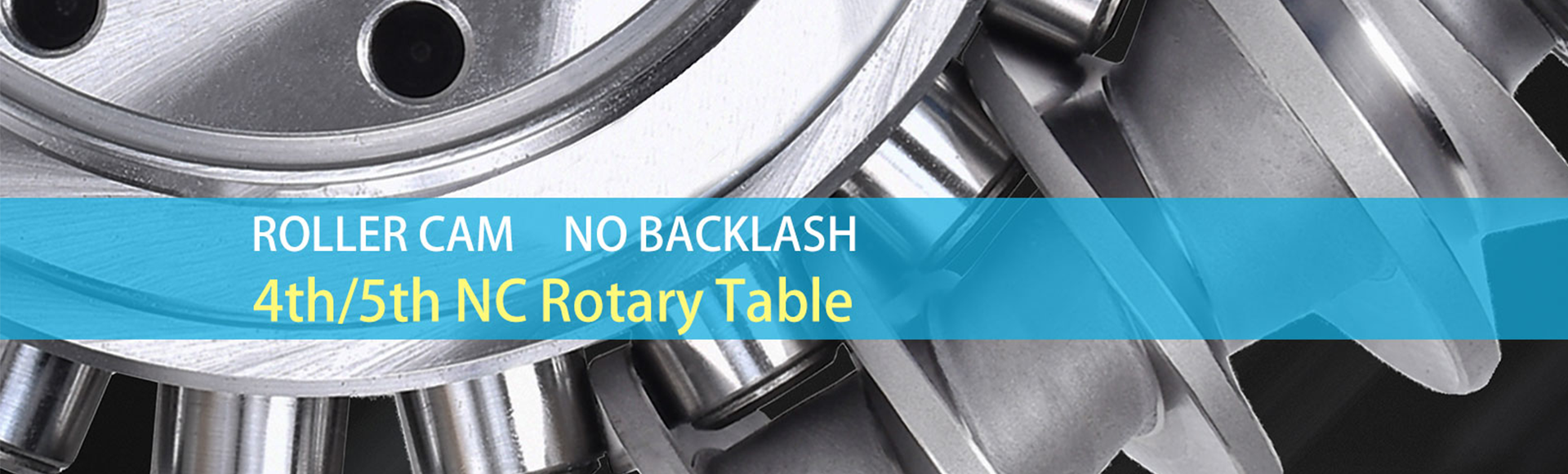

Rotary table: 4 axis rotary table, 5 axis tilting rotary table, hozirontal table, tailstock,

Probing system: optical touch probe, radio wave touch probe, wired touch probe,

Tool setting: laser tool setter , touch tigger tool setter, optoelectronic tool setter,

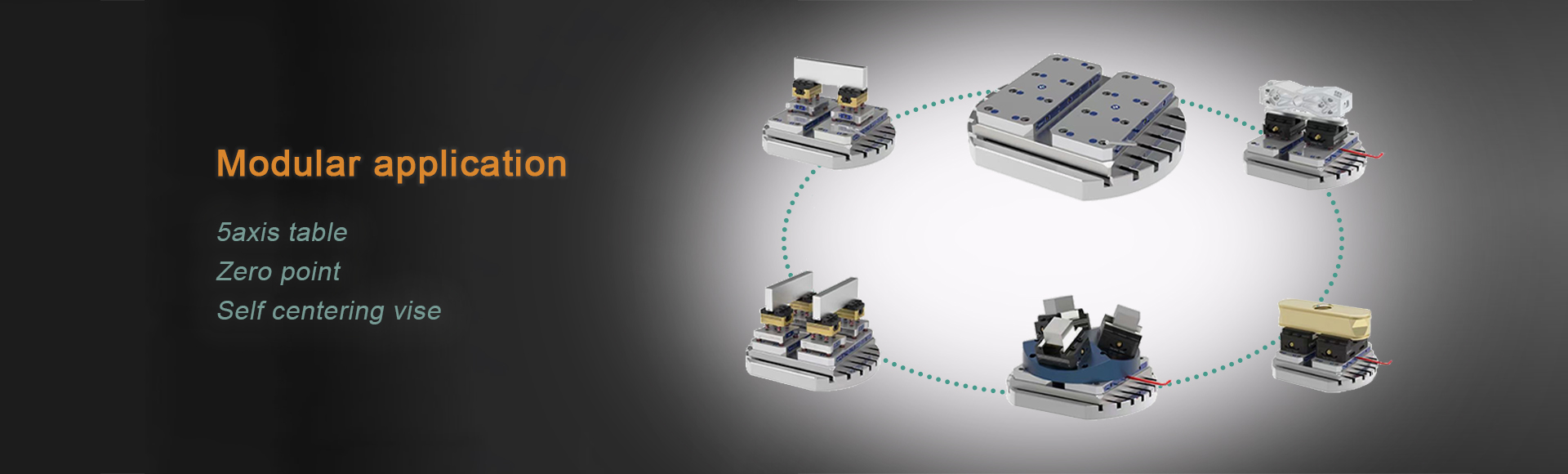

Zero point plate and workholding: Zero point clamping system, mechinical zero point, self centering vise.

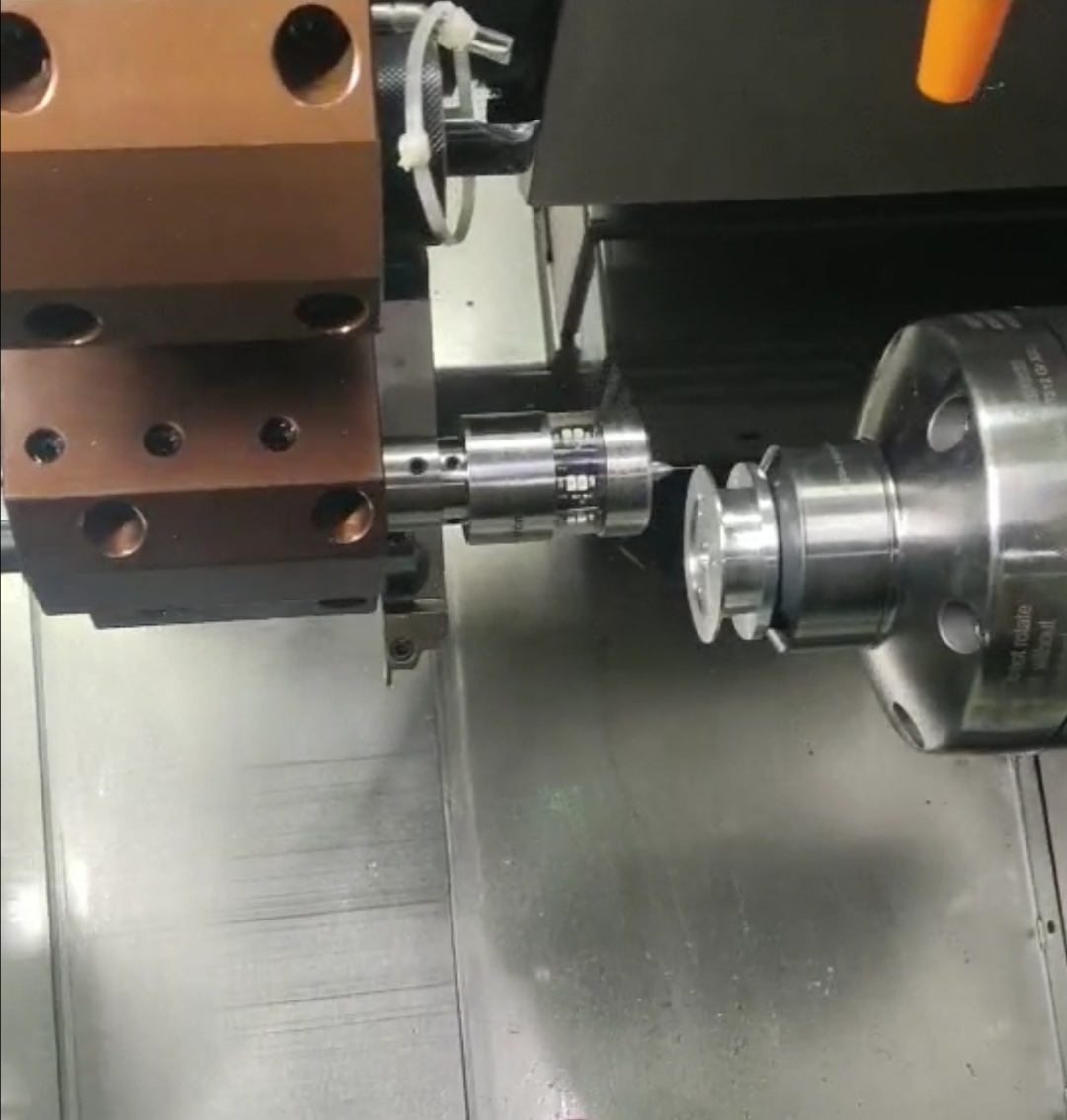

4th and 5th rotary table installed on machine tools can achieve multi-axis machining, position to nearly any angle or simultaneous machining

■ Fastest way to increase the productivity

■ Reduce setup times, increase part accuracy, and shorten cycle times

Touch probe used to identify and set-up parts, measure features in-cycle for adaptive machining, monitor workpiece surface condition and verify finished component dimensions.

■ Automatic fixture, job alignment and rotary axis set-up

■ In-cycle part measurement with automatic offset correction

■ First-off inspection with automatic offset update

■ Reduced machine downtime awaiting first-off inspection results

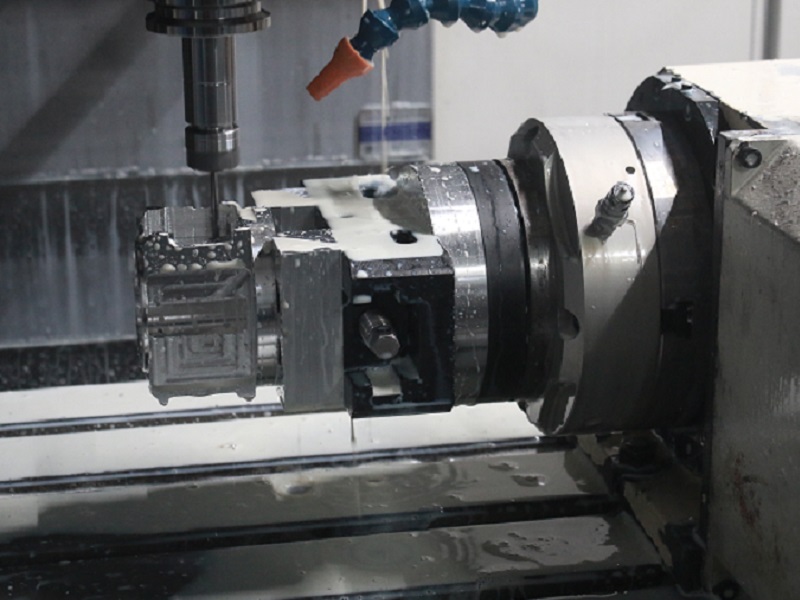

Tool setting used to measure the length of tools before cutting starts, and check for tool damage or breakage during the machining operation

■ Reduce scrap and increase productivity by accurately setting the length and diameter of cutting tools

■ Automatic tool offset calculation and correction

■ Significant time savings with reduced machine downtime

The zero point positioning system is a unique positioning and locking device, which can keep the workpiece from one station to another, from one process to another, or from one machine tool to another.

■ Time saving

Up to 90% time saving due to lower set-up, changeover and non-productive times.

■ Increased productivity

Up to 70 % more productivity in your manufacturing process.

Tool setter market situation and trends in China There is a strong demand for the tool setting in the Chinese market, According to statistics, China

China is the largest consumer of machine tool touch probes in the global market what’s the top 5 machine tool touch probe brand in China

Precision parts machining with rotary table The basic components of high-precision machinery, such as gears, cutting tools and bearings, have very high precision requirements and

Touch probe application in mobile phone house machining CNC Machining Requirements: Customers finish machining the installation position of internal key components on the basis of

Shenzhen Silvercnc Tech Co.,Ltd founded in 2013,which focus on CNC industry, providing the most suitable CNC machine and related accessories at the best price for our customers.

We sticks to the ISO 9001 quality management system. There are strict procedures and standards to regulate design, engineering, production, installation and service activities

Address : No.133,Bldg.12, Zhong Hai Xi An Hua Fu, Shajiang Road, Songgang Street, Bao An district, Shenzhen Worktime: 08:30-19:00 ( Beijing time) Email : [email protected]