Rotary table for auto parts machining

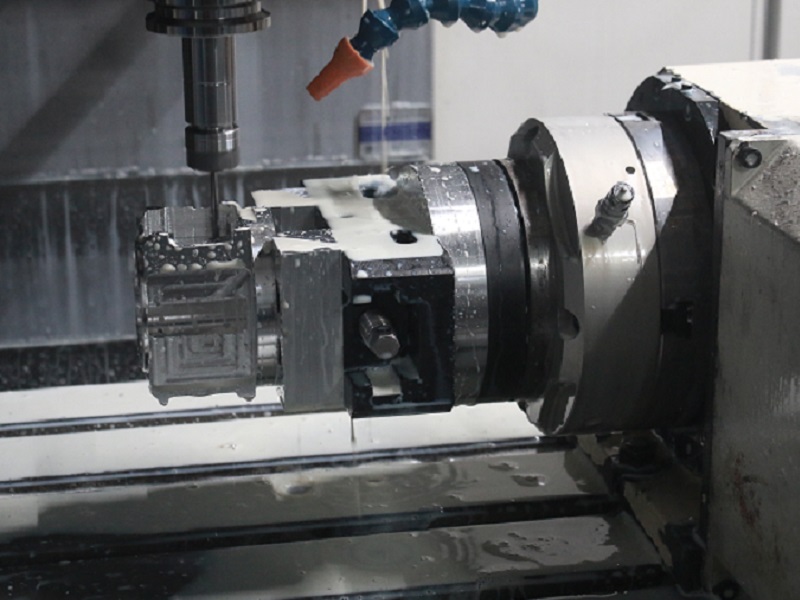

The booming automotive industry means new opportunities and challenges to Silvercnc 4/5 axis rotary table. Compared with 3C small parts industry, the processing of auto parts generally tends to large cutting and heavy cutting, and has higher requirements for NC rotary table. The processing of auto parts needs to be matched with professional fixtures customized by professional fixture manufacturers. Generally, the power of the hydraulic station is used to drive the hydraulic finger to press the parts through the hydraulic channel arranged inside the L block and fixture plate.

For the auto parts machining industry, silvercnc four axis five axis rotary table has the following advantages:

1、The fixture and workpiece of auto parts are generally biased. The sliding friction of worm rotary table will quickly wear the copper turbine and cause accuracy problems. The silvercnc adopt cam roller structure. The inside of the cam roller structure is rolling friction, and the cam and roller have the hardness of HRC60, with a service life of 5 million revolutions and no change in accuracy.

2、Many auto parts need to be processed on multiple surfaces. Using the index plate of four-axis five axis turntable can reduce the number of product clamping and greatly improve the production efficiency and qualification rate. Reduce the number of workers and labor intensity

3、Auto parts tend to be subject to large cutting and heavy cutting. Silvercnc rotary table C180 or above are equipped with hydraulic embracing brake as standard, with large braking torque and motionless workpiece after braking. the machining is stable, improving the production efficiency and reduce the scrap rategreatly .

4、Auto parts have the characteristics of fast updating and upgrading. The rotary table is matched with external control system to control turntable. Solve the problem that the machining center cannot open the four axis and five axis function and electrical installation and commissioning, and achieve plug and play.

5、Our rotary table always maintained close cooperation with professional automobile fixture manufacturers to provide customers with one-stop services such as complete CNC rotary table, fixture and peripheral accessories, programming and debugging, installation, after-sales maintenance and so on.

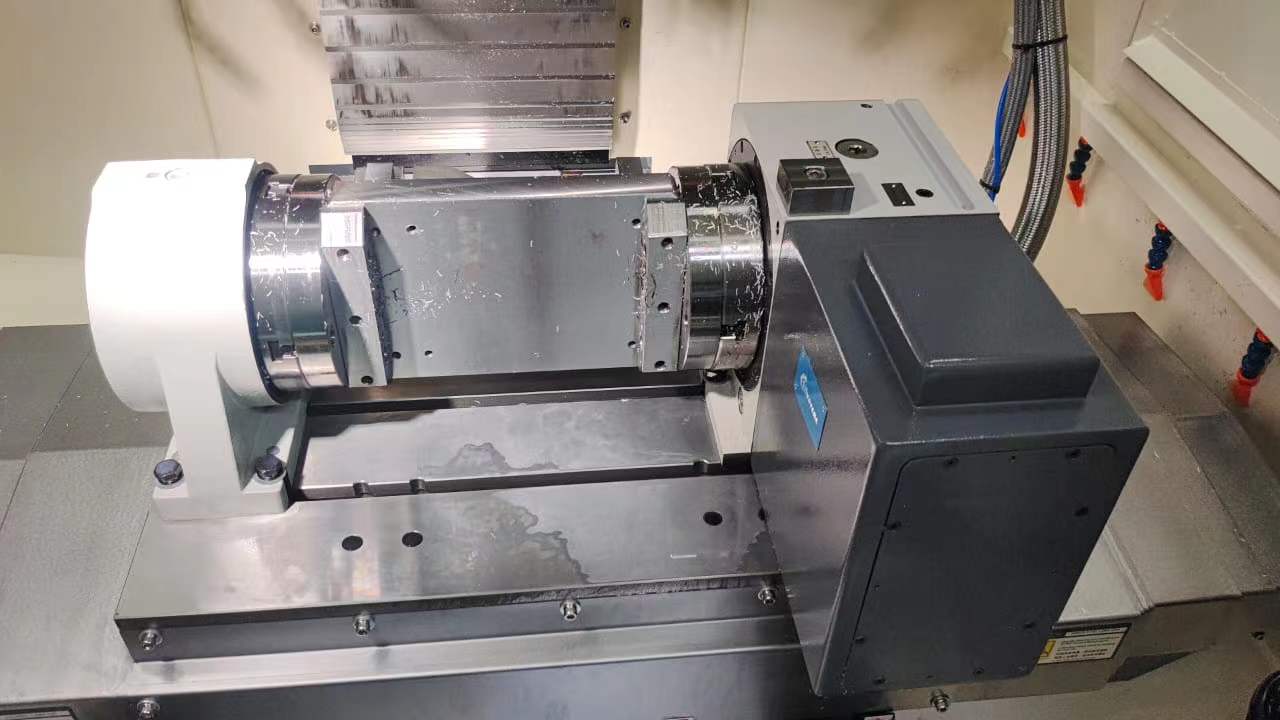

rotary table with fixture

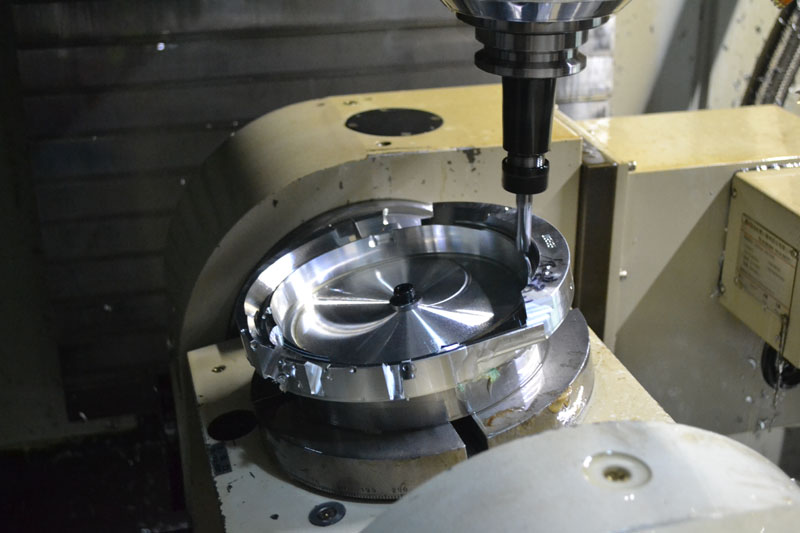

Machining die casting of automobile engine case with rotary table

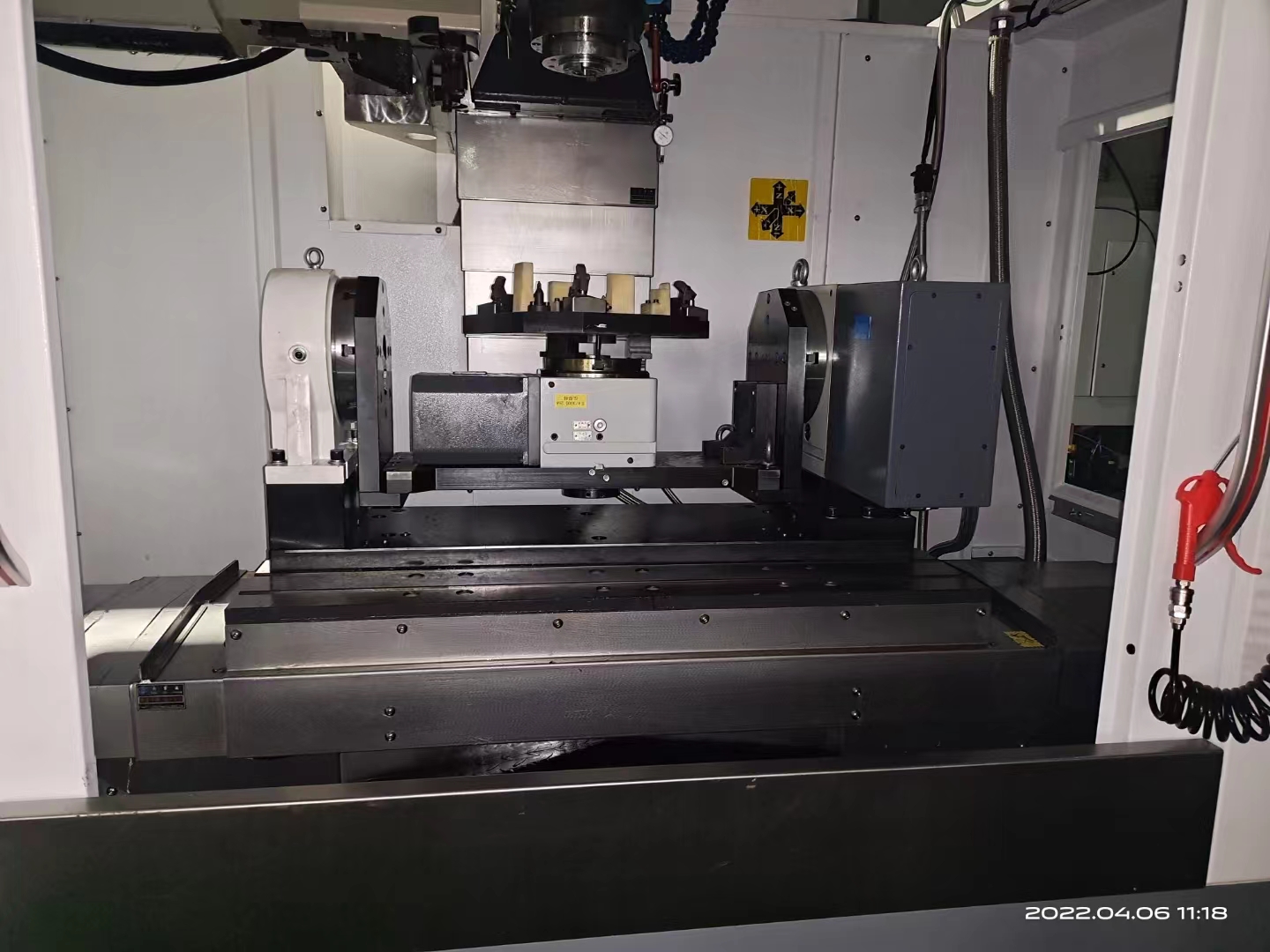

rotary table on mazak VMC for automobile parts machining

rotary table on haas VMC for automobile parts machining