Laser tool setter basic and function

Laser tool setting has increasingly become an indispensable tool in precision machining. with the change of light beam between the laser transmitter and the receiver to trigger the signal, it measures tool through various software and macro programs

When the tool passes the laser beam, the light intensity at the receiver decreases, sending a signal to the controller to record the current machine position and obtain the tool size (diameter or length) from the surface. If the tool moves quickly, but the light signal is received which should be blocked, that means the tool is broken. The laser detection working with the spindle speed can identify the errors caused by the uncoordinated clamping and radial runout of the spindle, tool and tool holder

Touch trigger tool setter VS Non contact laser tool setter

Please check the comparison table below

Function | Touch tool setter | laser tool setter | Remarks |

Tool length and diameter | Yes | Yes | / |

Tool wear | Yes | Yes | / |

Tool break | Yes | Yes | / |

Tool profile detection | No | Yes | Special-shaped tool, multi-tooth tool |

Thermal compensation | No | Yes | Thermal deformation of machine tool spindle |

Minimum tool diameter /mm | 0.5mm | 0.03mm | / |

Super hard knife detection | No | Yes | Thermal deformation of machine tool spindle |

Several important designs of non contact laser tool setter

1. Optical protection system

The working environment of the laser tool setter is poor, and the cutting oil, fluid and chips in the machine tool often interfere with the laser signal. Effective measures need to be taken to protect the sensitive laser barrier optical system to avoid frequent alarm caused by interference signals.

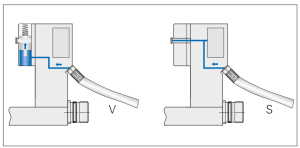

Mechanical protection:

The laser tool setter system generally has a unique mechanical sealing system, such as the spring structure design shown in Figure v. the sealing structure makes the optical system only effective during the measurement period, and can also avoid the pollution of the optical device caused by the shutdown of the air source.

Compressed air circuit

As shown in figure s, the laser system will use continuous compressed air flow to pass through a precisely designed micro laser hole. The airflow flows out of the micropores at a certain speed to remove any coolant and chips entering the laser system, providing protection for the tool setter in the actual processing environment.

2. Drip proof design:

Software and program are used to actively identify and filter the interference of water droplets, which greatly reduces the probability of false alarm

3. Compressed air drying protection device

Provides clean and dry air for laser tool setter system and prevents from contamination by coolant and chip. Simple installation

Brand recommendation of laser tool setter

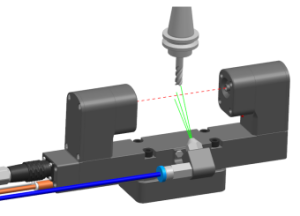

1.Renishaw NC4

Renishaw NC4 non-contact laser tool setting can detect the minimum tool diameter of 0.03mm, and the repeated detection accuracy is ± 0.1um. Other brands of laser tool setting systems use red laser beams, while NC4+ blue is the first blue laser tool setting instrument in the industry. The shorter wavelength of blue laser can improve the diffraction effect and optimize the geometry of laser beam. Higher measurement accuracy.

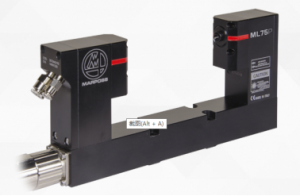

2. Marposs Mida Laser 75P

The laser tool setting system Mida laser 75p for tool detection of Marposs machine tool has a detection repeatability ≤ 0.2um. Using focused laser beam, the minimum measurable diameter is ≤ 50um. With its measurement software, it can set the tool quickly and reliably, and get the tool size in the same state as the real machining speed and feed speed. The measured tool size is automatically brought and the tool compensation table of the CNC controller is updated to avoid any possible errors caused by manual input.

SILVERCNC laser tool setting adopts focused laser beam and optimizes the technology of Renishaw and Blum laser system. It can detect the minimum tool diameter of 0.03mm, and the repeated detection accuracy is ± 0.1um. With ultra-high precision, high-grade sealing protection and high stability. It is the highest cost performance brand, price is only 3850 USD around in China market.