3D Touch Trigger Tool Setter

3D Touch trigger tool setter for tool length and radius measurement as well as tool breakage detection

3D touch-trigger tool setter with hard-wired signal transmission in CNC machining centers, Precise and reliable measurements similar to a wired touch probe

Brand: SILVERCNC

Models: S5TS

Logo printing : Silvercnc/WDS/None/Customized

Surface finishing: Grinding 4s

Repeatability: 1um

Contact life: 10million

Contact materia: Tungsten carbide

Cable: 5m(can customized)

Warranty: 1 year

Packaging Details: carton

Shipping: DHL/TNT/UPS, 3-7 days

S5TS Tool setter benefits

■ High machining accuracy requires an exact measurement of tool data and cyclical inspection of tool broken and wear.

■ With the S5TS wired tool setter,engineer can setting the tool automatic, setter up faster, improve quality and reduce scrap.

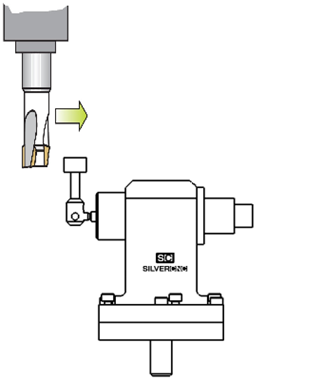

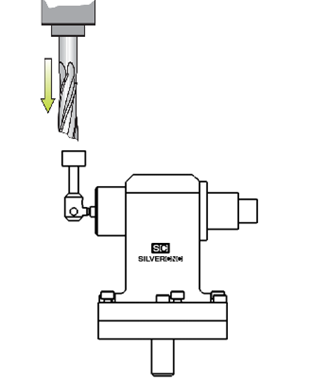

■ Using the S5TS to measure tools wear and tool breakage monitoring, the machine will alarm automatic when exceeding allowable value, reminding tool compensation.

■ Automatic operation, save labor, prevent the emergence of substandard products

■ Applicable to the Engraving machine and all kinds of control machinery in Japan, Taiwan, South Korea, China, Germany. Such as fanuc, SYNTEC, Baoyuan, Siemens, FAGOR, Mitsubishi, etc.

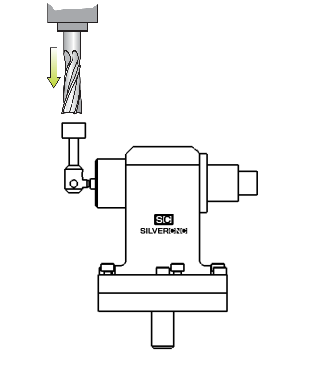

Automated tool setting

• Establish height offsets and check tool length is within tolerance

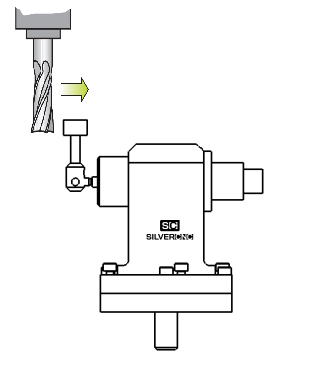

• Determine diameter when spinning to establish tool size offsets

• Manual setting errors and data entry

In-process control

Detect broken tools in-process

Compensation of tool wear using measurements between the machining steps.

Tool length measurement

Tool radius measurement

Tool wear measurement

Tool breakage monitoring

S5TS Tool setter fetures

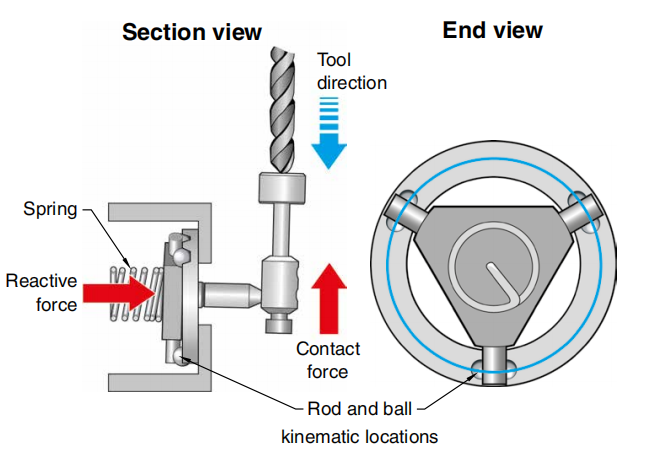

Perfect mechanical structure

The tool setter use a proven technology -kinematic resistive principle(the same as renishaw) that can stably operate for long time.

Proven over four decades, this design has been the main choice for the majority of machine builders and end users to ensure accuracy and reliability.

The ability of the probe mechanism to reseat after triggering to within 1.00 µm is fundamental for repeatability and good metrology.

From simple length and radius checking to broken tool detection, this technology is available in silvercnc touch probe and contact tool setters.

Feature:

- Double function measurement of tool length and tool diameter

- Repeat positioning accuracy <1um

- Super IP68 level protection, double protection structure

- 10 million contact life

- It is suitable for all kinds of CNC machine tools with mounting tables that do not need rotatio

Specification

Model | S5TS |

Output | NO(Normally open) |

Sense directions | 5 axis |

Pre-travel | 0 |

Travel | +/-12.5°, Z-6.35mm |

Repeatability | <1um |

Trigger life | >10million |

Protect | IP68 |

Contact force | 0.4N~0.8N, Z-4.0N |

Signal transmission | Cable |

Contact material | Tungsten carbide |

Surface finishing | Grinding 4s |

Rated voltage and current | DC24V 20mA |

Cable | Oil resistant,standard3m(length can be customized)Minimum radius R7 |

LED lamp | Default: LED OFF/Operating: LED ON |