Touch probe application in mobile phone house machining

CNC Machining Requirements:

Customers finish machining the installation position of internal key components on the basis of rough machined or stamping parts.

Such as iphone hole, volume key, on-off key, lens hole, fixed position of electronic components, etc. The general accuracy is required to be 0.01-0.03mm.

Difficulties and problems when machining

- datum deviation caused by workpiece clamping leads to machining accuracy deviation

- product clamping will lead to secondary deformation and machining accuracy deviation

- machining accuracy deviation caused by unstable incoming dimension of stamping parts

- machining accuracy deviation caused by tool wear

- processing waste caused by tool breakage

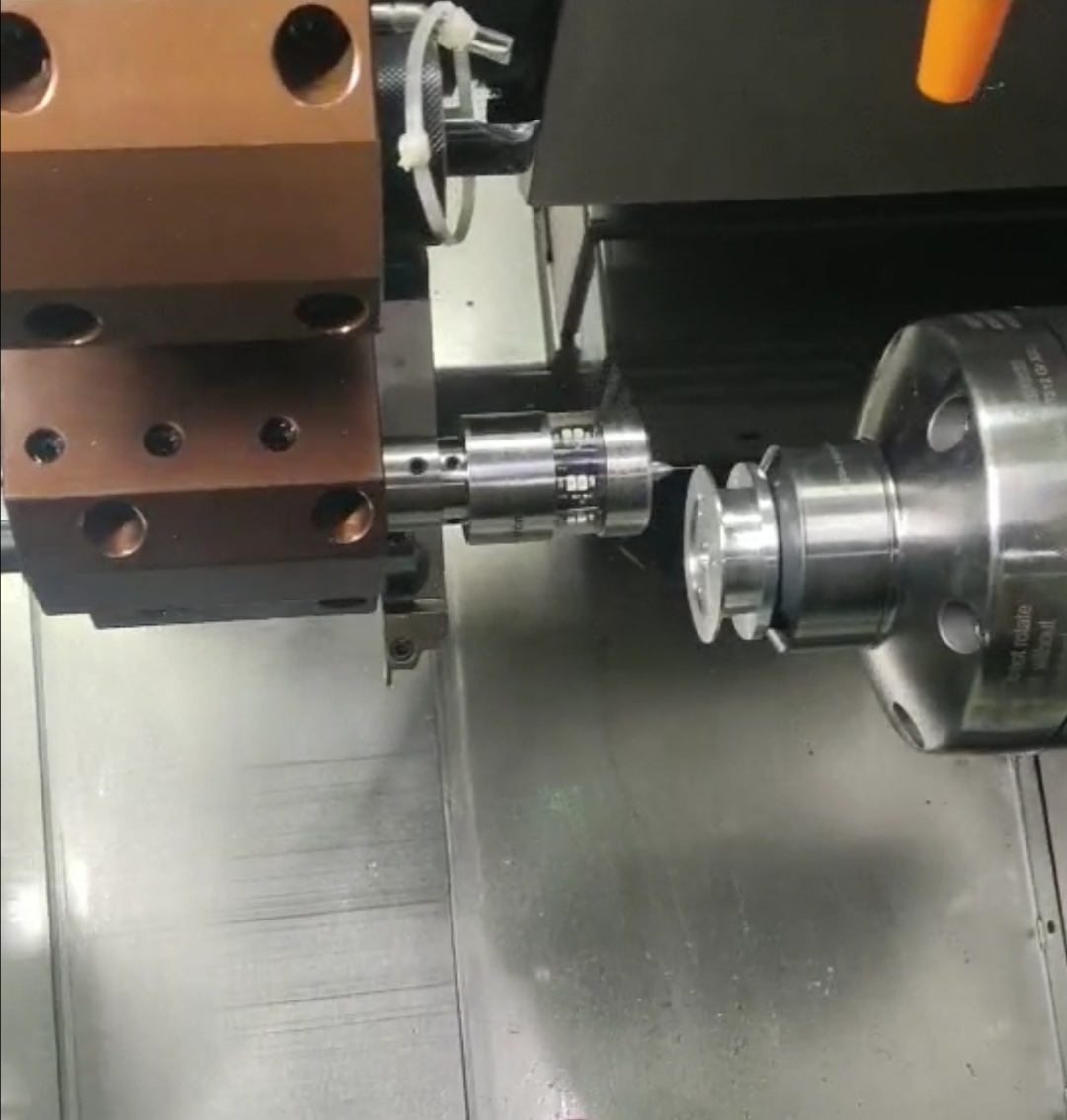

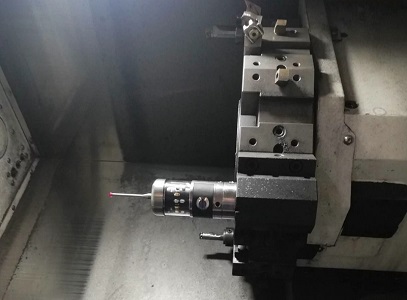

Infrared touch probe solution

The machine is equipped with dop40 touch probe and tool setter. After the workpiece is fixed in the fixture, by using the measurement program and machine tool probe, align the 4-side division and reference z plane of the workpiece, find the actual position of each product, and automatically update the actual position value to the machining coordinate system to realize the automatic setting of machining benchmark. In the process of machining, the tool breaking detection and tool damage supplement are automatically carried out by calling the tool setting program

Benefit

The yield of products has been greatly improved. At present, in the application of battery cover and mobile phone house, the probe has become the standard configuration, and the configuration proportion of tool setting instrument is also rising rapidly

Recommended configuration

Infrared probe dop40 + tool setting