Horizontal Rotary Table

High quality and Affordable Horizontal Rotary Table From China Manufacturer

Horizontal CNC rotary table from SILVERCNC delivers high precision, rigidity, and durability, enhancing your machine tool’s capacity for efficient multi-axis machining. It it a reliable choice for precision manufacturing.

- High strength FC30 cast iron is used for manufacturing

- Suitable for horizontal machining center or other special machine for cutting

- The new spindle locking system, compared with the traditional bilateral platen, has stronger locking and more stable cutting

- Can do 360 pass turn, turn the handle one turn for 4 degrees, the minimum positioning unit is 0.001 degrees

Brand: SILVERCNC

Port: Shenzhen China

Logo printing : Silvercnc/WDS/None/Customized

Certification: ISO9001

Models: H500, H630, H800

Spec.: 0.001°,1°, 5°,15°

positional: ±15 arc.sec

Repeatability: ±4 arc.sec

Warranty: 1 year

Packaging Details: Wooden box

Shipping: DHL/TNT/UPS, 3-7 days

Specifications of Horizontal Rotary Table

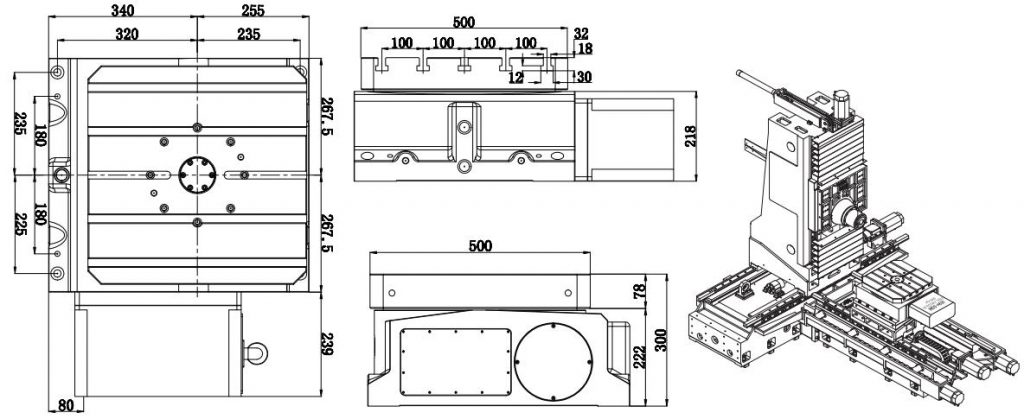

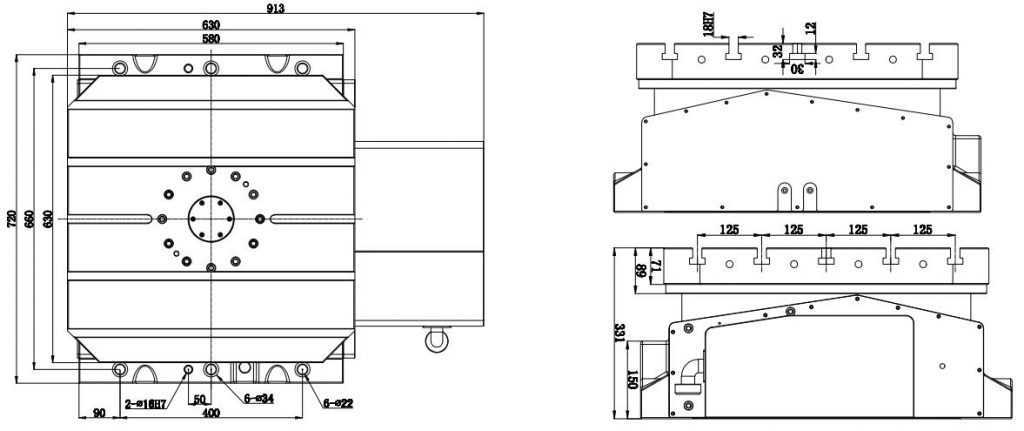

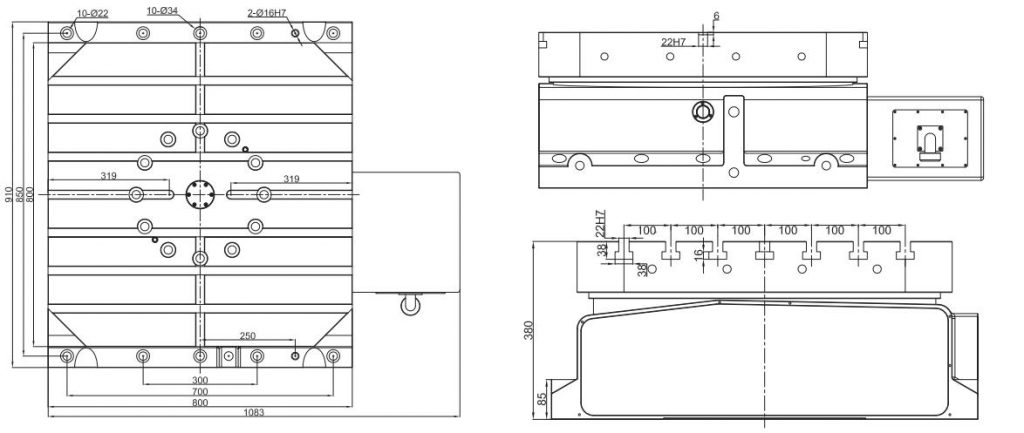

| Description | unit | SILVER-H500 | SILVER-H630 | SILVER-H800 | |

| Table Diameter | mm | 500 | 630 | 800 | |

| Allowable Workpiece Load | kg | 600 | 1200 | 2500 | |

| Min. Increment | deg | 0.001° | 0.001° | 0.001° | |

| T-Slot | mm | 18H7 | 18H7 | 22H7 | |

| Indexing Precision | arc.sec. | ±15 | ±15 | ±15 | |

| Repeatability | arc.sec. | ±4 | ±4 | ±4 | |

| Speed Reduction Ratio | / | 1/180 | 1/180 | 1/180 | |

| Rated / Max. Speed | rpm | 11.1 | 11.1 | 11.1 | |

| Diameter of Table Central Hole | mm | Ø50H7 | Ø50H7 | Ø50H7 | |

| Net Weight (servo motor excluded) | kg | 530 | 600 | 1210 | |

| Strength of Roller Gear Cam | N.m | 2450 | 3700 | 6400 | |

| Clamping System(Hydraulic) | Mpa | 5 | 5 | 5 | |

| Clamping Torque | N.m | 2860 | 3900 | 8000 | |

Silver-H500

Silver-H630

Silver-H800

Benefits of Our Hortizontal Rotary Table

High Precision

The roller CAM design ensures ultra-precision by completely eliminating backlash. This is achieved by precompression processing, which ensures the roller and CAM mesh perfectly. This results in very accurate movement。Energy Efficiency

The rolling contact mechanism reduces friction, improving energy efficiency. With a transmission efficiency as high as 90%, the rotary table consumes less power, which reduces operating costs.High Rigidity

The design also provides high rigidity, which ensures stability during machining. The rotary table can maintain accuracy under heavy loads, preventing any movement of the workpiece。Durability

The precompression processing ensures smooth contact between the roller and CAM, which significantly reduces wear and tear. This enhances the durability of the rotary table, making it reliable for long-term use

Related Rotary Table and Its Accessories

Frequent Asked Questions (FAQs)

A horizontal CNC rotary table is a specialized accessory used in CNC (Computer Numerical Control) machining to provide automated, precise rotational movement of the workpiece around a horizontal axis. It is mounted on a CNC machine, such as a milling machine, to rotate the workpiece during machining operations, enabling multiple sides or complex features to be processed without the need for manual repositioning.

Unlike traditional manual rotary tables, a CNC rotary table is controlled by the CNC system, allowing for highly accurate indexing and rotation based on programmed commands. This automation improves machining efficiency, reduces human error, and allows for complex, multi-axis operations.

Horizontal CNC rotary tables are versatile tools that expand the capabilities of CNC machines. Here are the main applications:

- Multi-Sided Machining: Rotate workpieces for machining multiple sides without repositioning, improving efficiency and precision.

- 4th and 5th Axis Machining: Enable complex part geometries by adding rotational movement along additional axes for intricate milling and drilling tasks.

- Drilling and Tapping: Automate precise hole drilling and tapping at various angles for accuracy and speed.

- Grinding and Polishing: Rotate parts evenly for uniform surface grinding and polishing.

- Welding: Facilitate continuous, uniform welding by rotating large components for access from multiple angles.

- Part Marking and Engraving: Mark or engrave on multiple faces of a workpiece with high precision.

- Aerospace and Automotive: Used for high-precision parts like engine components, turbine blades, and structural elements.

Horizontal rotary table rotates around a horizontal axis, meaning the workpiece is positioned flat on the table and rotates side-to-side. It is best for heavy, large parts and multi-sided machining. It’s more stable for larger workpieces and ideal for tasks like milling, drilling, and grinding.

Vertical rotary table rotates around a vertical axis, with the workpiece standing upright and rotating up and down. It is often used for smaller, lighter parts and is ideal for applications requiring less space for rotation, like engraving tasks.

- Tailstocks: Used to support longer workpieces during machining.

- Chucks: Securely hold the workpiece in place.

- Clamps and Fixtures: Help secure the workpiece at specific angles.

- Dividing Heads: Enable precise indexing for complex machining tasks.