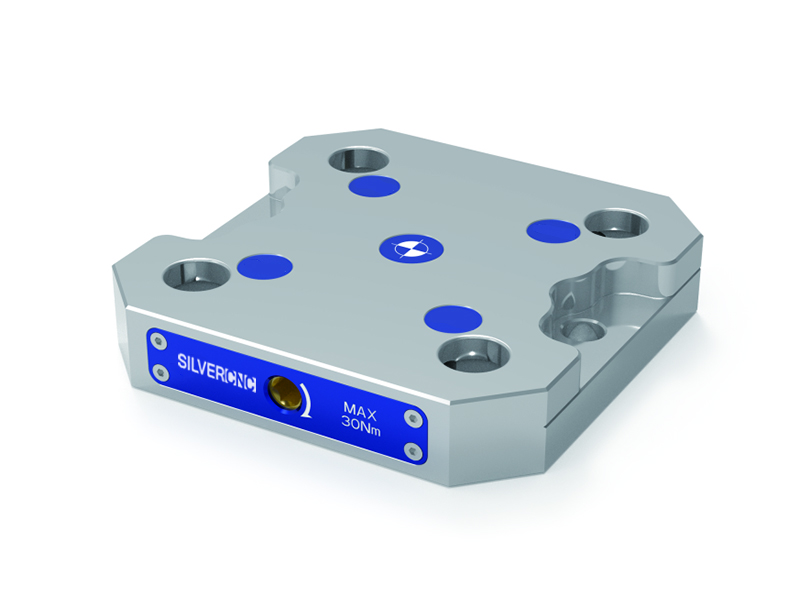

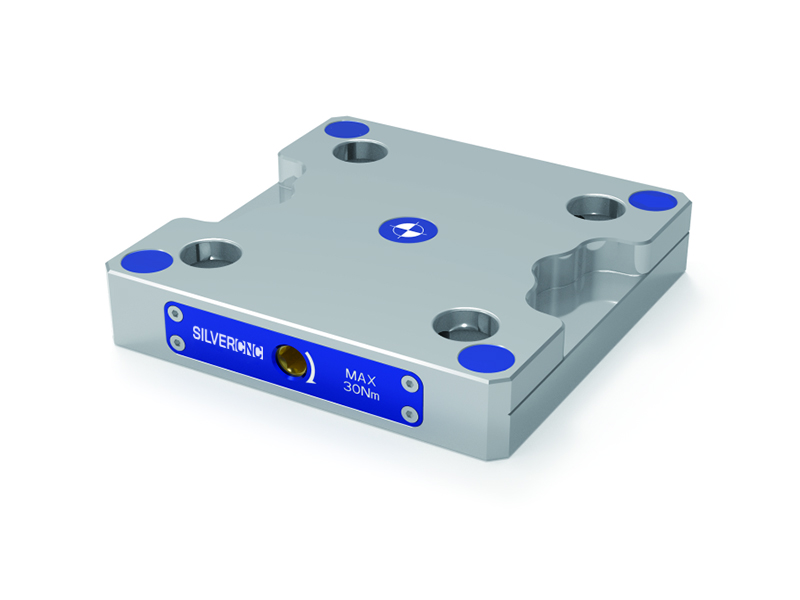

Mechanical zero point base plate

Best Quality Zero Point CNC Base Plate China Manufacturer - SILVERCNC

SILVERCNC manufactures and supplies zero point plates with standard 52mm and 96mm stud spacing options. These CNC base plates are made from high-quality alloy steel, ensuring exceptional strength and durability.

The surfaces are typically hardened to HRC57, enhancing wear resistance and extending service life, making them ideal for long-term, high-demand industrial applications.

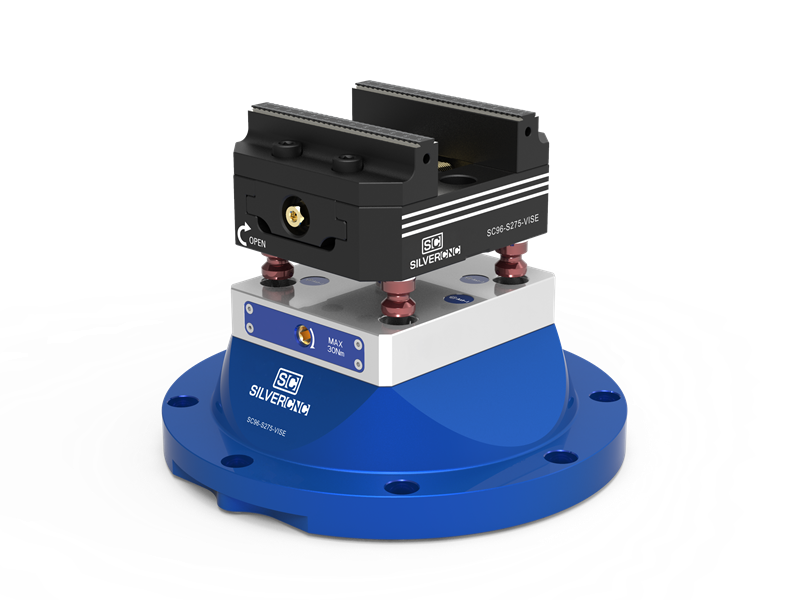

■ Compact Design,4-point clamping by only one actuation screw

■ Strong clamping with 14 kN force allows heavy duty machining

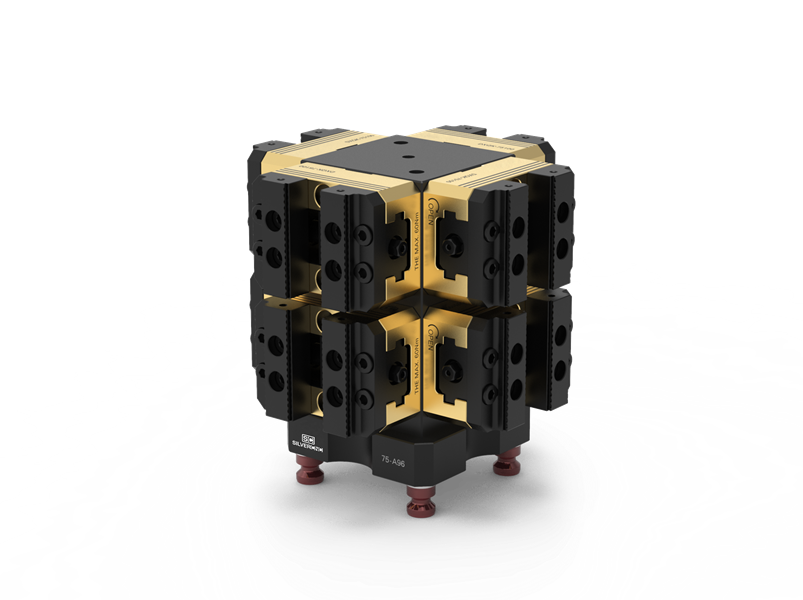

■ Multiple workpieces holding, maximizes fixture spaces for clamping multiple workpieces

■ 2 jaws locate and clamp the pull studs with high accuracy, precise and quick fixture change

Product Descriptions - Zero Point Plates

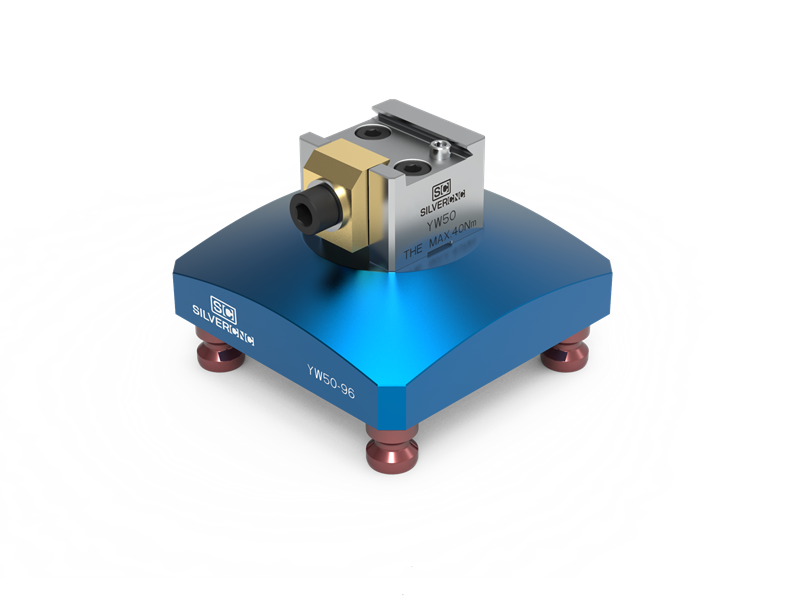

Various workholding fixtures like self centering vise can be rapidly changed on the zero point plates. Our cnc fixture plate enables an increase in machine run-time and manufacturing quality. The change of the clamping devices is done only by a central clamping screw. Due to the flat design and the fixturing holes of the zero-point-system an universal mounting on the machine table or on fixturing devices is possible

■Reliable structural designs, Silvercnc zero point plate has similar function as 5 axis

■0.005mm repeatability

■Clamping force up to 15000N

■Size and center distance can be customized

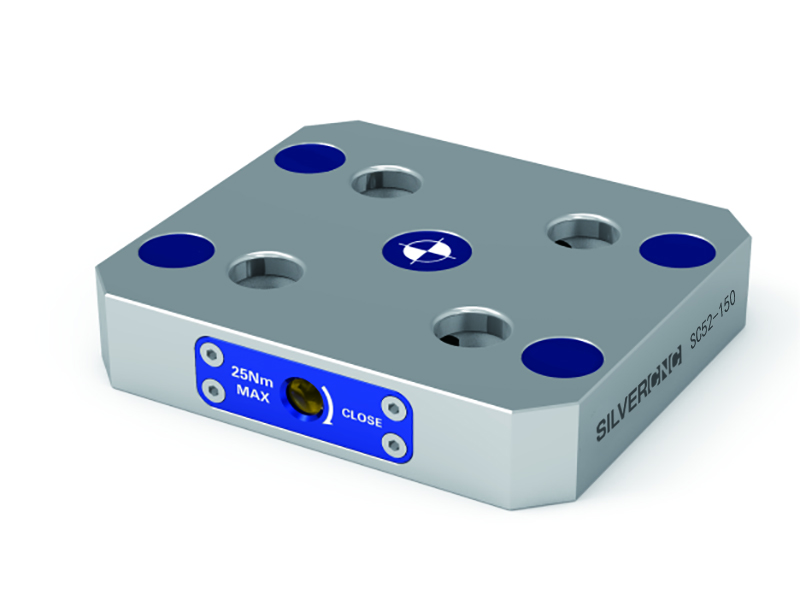

52mm mechanical zero point cNC base plate

SC52-S96

SC52-S120

SC52-S145

SC52-S150

For dimensions information,click the download catalog

Model | SC52-S96 | SC52-S120 | SC52-S145 | SC52-150 |

Dimessions/mm | 121*121*25 | 106*106*25 | 106*106*25 | 120*106*25 |

Repeatability/mm | 0.005 | 0.005 | 0.005 | 0.005 |

Clamping force/KN | 18 | 18 | 18 | 18 |

Material | steel | steel | steel | steel |

Weight/Kg | 2.4 | 1.6 | 1.8 | 2 |

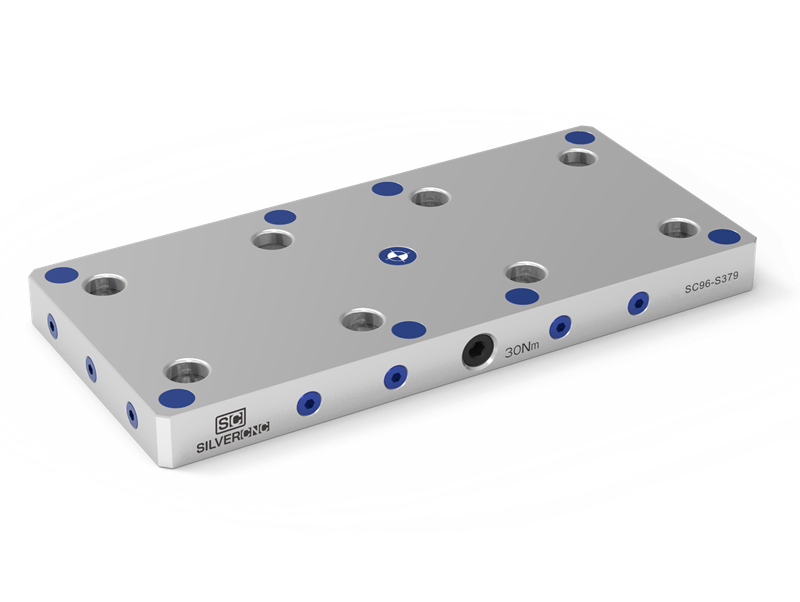

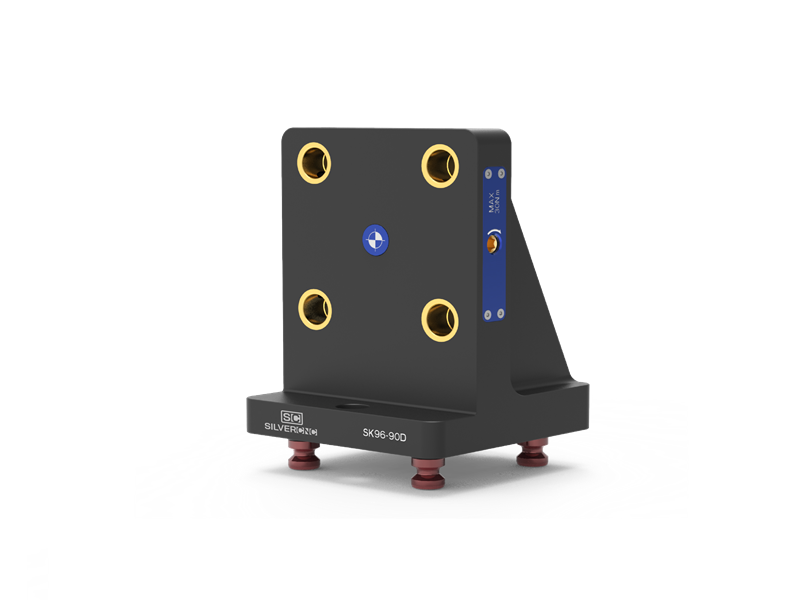

96mm mechanical zero point CNC base plate

SC96-S190

SC96-S195

SC96-S200

SC96-S205

For dimensions information,click the download catalog

Model | SC96-S190 | SC96-S195 | SC96-S200 | SC96-S205 |

Dimessions/mm | 150*150*30 | 150*128*30 | 168*150*30 | 150*150*30 |

Repeatability/mm | 0.005 | 0.005 | 0.005 | 0.005 |

Clamping force/KN | 22 | 22 | 22 | 22 |

Material | steel | steel | steel | steel |

Weight/Kg | 4 | 4.6 | 5 | 4 |

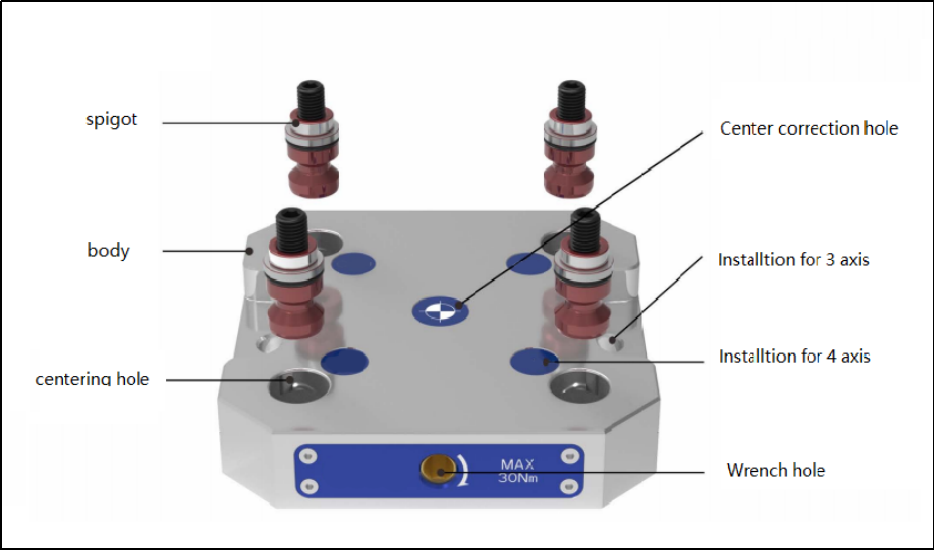

Zero Point Plate: Basic Structure and Key Components

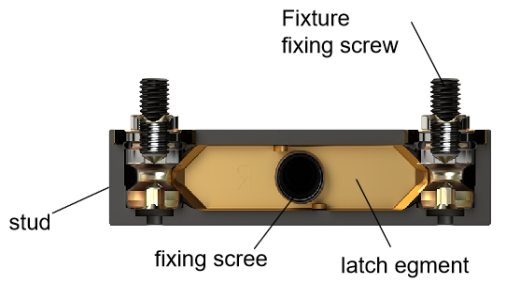

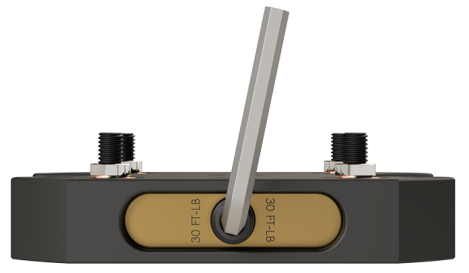

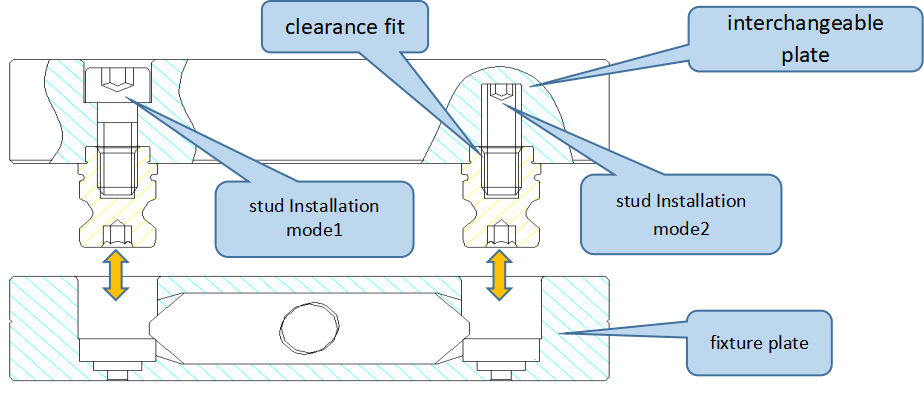

■ Zero point base plate consists of a base plate, precision wedge blocks, and 4 precision studs components.

■ Stud has two precise positioning surfaces, one fits with the workpiece and the other fits with the base plate.

■ The four positioning holes on the base plate are grind to ensure repeatability accuracy of less than 0.005mm.

■ Standard 52 and 96 Latin spacing design for quick interchangeability of various fixtures

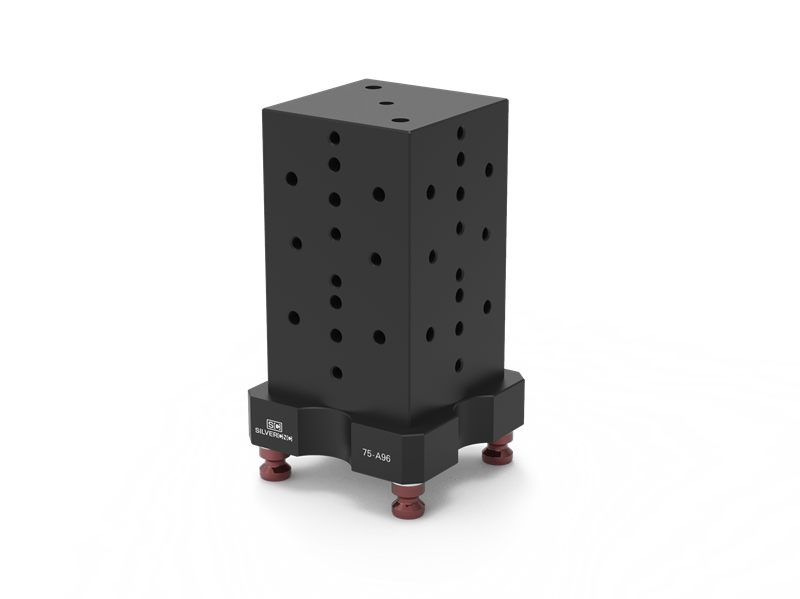

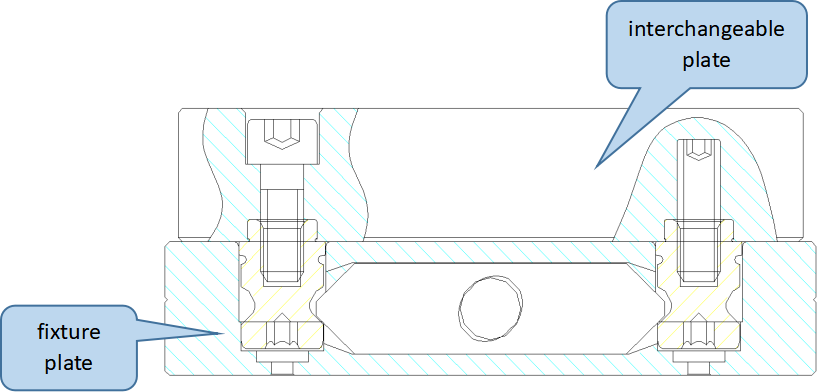

Various modular fixture integration

With our mechanical zero point base plate, you can design various cnc workholding fixtures flexibly, and exchange them among three-axis, four axis and five axis machine tools quickly to reduce the downtime of the machine tool

Seperate state

Locked state

FAQs

What is a Fixture Plate?

A fixture plate is a tool used in CNC machining to hold workpieces securely during the machining process. It provides a stable surface to attach and align parts, ensuring precision and accuracy. Fixture plates are often used to improve efficiency and repeatability in CNC operations, reducing errors and setup time.

What is the Purpose of a CNC Base Plate?

A CNC base plate serves as the foundation for a CNC machine setup. It holds and supports the workpiece while it is being machined. The base plate helps to position the part accurately, reducing movement during the cutting process. It also increases the stability of the machine, ensuring more precise cuts and improving the overall quality of the finished product.

What Material Are CNC Fixture Plates Made From?

CNC fixture plates are typically made from high-strength materials like alloy steel or aluminum. Alloy steel is commonly used for its durability and ability to withstand wear and tear. Aluminum fixture plates are lightweight and corrosion-resistant, making them suitable for lighter applications. The choice of material depends on the machining requirements and the type of workpieces being used.

How Thick Should a CNC Base Plate Be?

The thickness of a CNC base plate depends on the size of the workpiece and the machine’s requirements. Typically, base plates are between 10mm and 50mm thick. Thicker plates provide better stability and are used for heavier or larger workpieces.

It’s important to choose the right thickness to ensure the base plate can handle the forces involved in the machining process while maintaining accuracy. SILVERCNC provides 25mm and 30mm thick zero point plates.