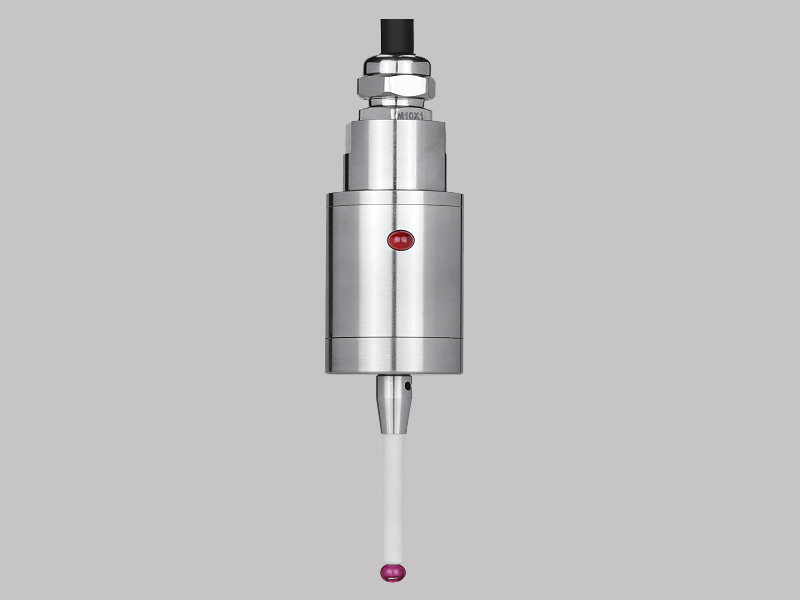

Radio Wave Touch Probe

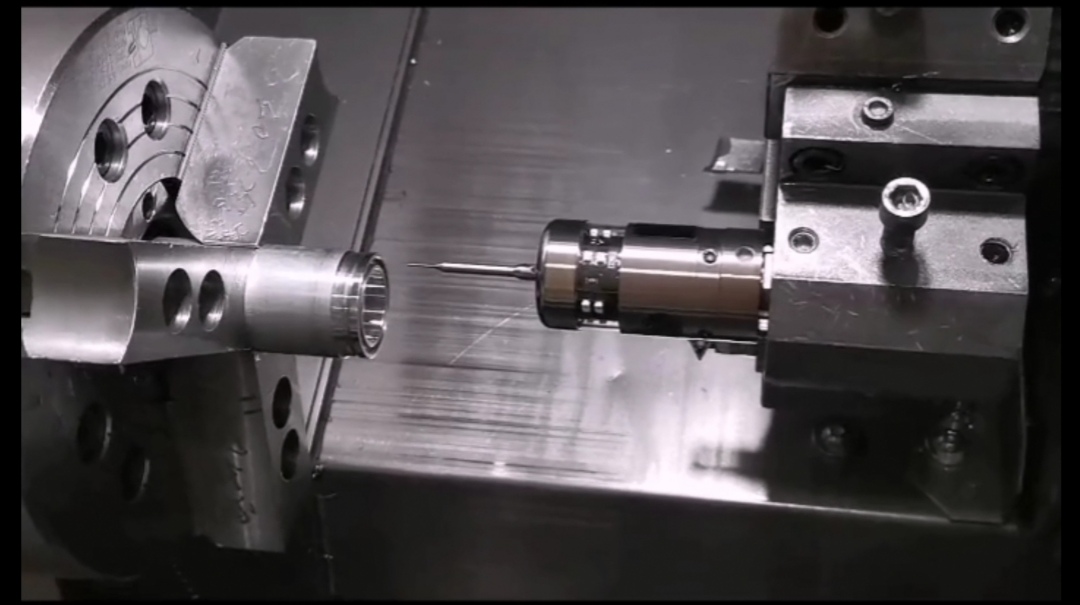

Radio wave touch Probe on Machine tool used For Component Setting And Inspection

The touch probe specially designed used in signal transmission distance or obstacle requirements of the machine and occasions. Precision and performance are close to Renishaw

Brand: SILVERCNC

Models: SRMP40

Logo printing : Silvercnc/WDS/None/Customized

Certification: ISO9001

Signal transmission: Radio Wave

Repeatability: 1um (2σ)

Operating range: 15m

battery life: >360 days

Warranty: 1 year

Packaging Details: carton

Shipping: DHL/TNT/UPS, 3-7 days

Radio wave touch probes basic:

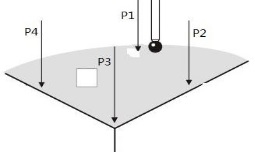

when the probe stylus When approaching a workpiece surface, the stylus deflects, and when the deformation reaches a certain degree, the internal current value will change,as a result a trigger signal happend. the signal transmitted to the receiver by radio wave, which converts the radio waves to an electrical signal sent to the machine tool control.

Perfect mechanical structure design

Infrared probe and radio probe have a same mechanical structure

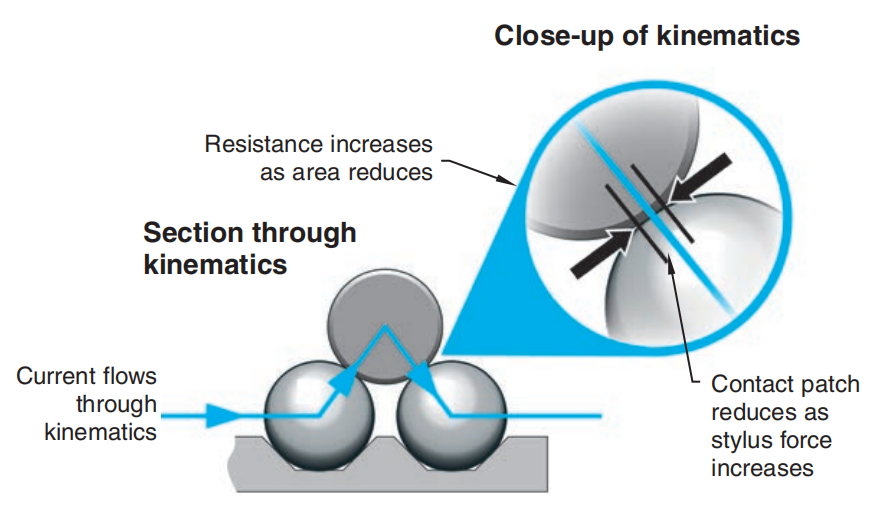

(1) Silvercnc SRMP40 touch probe use a proven technology -kinematic resistive principle that can stably operate for long time

(2) it can realize extremely precise measurements under standard 50mm probe styli at 600mm/min speed

(3) The balls and rods of the probe adopt special process to ensure 10 million times life, to ensure excellent stability

(4)we research and development a micro swing autonomous reset technology independent , successfully solved the problem of poor stability and unstable repeated . now silvercnc probe have excellent stability performance, high repeated positioning accuracy

Reliable signal transmission

(1) The rado wave touch probe applies intelligent frequency conversion technology independently developed by our company, matching the channel between probe and receiver intelligently , which solves the problem that radio probe and receiver can not be interchanged perfectly or no troublesome when interchanging .

(2) SRMP40 probe adapt the original multilevel combination counter code technology, the number of probe channels is unlimited, which solves the problem that the number of radio channels is less than 100 in the industry.

Longest battery life in probe system

(1) The system adopts the multi-threshold power consumption control technology, which greatly reduces the product power consumption, and by optimizing the chip design and circuit design, improves the battery life further.

(2) Battery life: silvercnc touch probe life is long, continue use >360 days, 5% use >540 days, Standby >600 days,Battery life is much higher than other brands

Easy to install

(1) The installation of the probe receiver is a troublesome job, which requires drilling holes in the machine tool for fixing.

(2) We designed a magnetic mounting base that allows the receiver to be mounted on the base and then attached together to the sheet metal of the machine tool, reducing installation difficulty.

SRMP 40 radio wave touch probe system has very good performance. Several important parameters , such as repetition accuracy, stability and response time, are close to international well-known brand.please check the parameters below:

| Model | SRMP40 | |

| Unidirectional repeatability Use standard 50mm probe at 600mm/min speed | 1um (2σ) | |

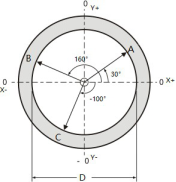

| Sense directions | ±X,±Y,+Z | |

| Stylus trigger force Use standard 50mm probe | XY plane 0.4 – 0.8N | Z direction 4.0N |

| Trigger protection trip | XY plane +/-15° | Z direction 6.35mm |

| Signal transmission method | radio transmission | |

| Operating range | 15m | |

| Trigger life | >10 Million times | |

| Transmission angle | 360 ° along the probe axis | |

| radio frequency | 433.075MHz-434.650MHz | |

| Radio channel number | 64 | |

| Transmission on/off style | smart switch | |

| Weight without shank (including batteries) | 280g | |

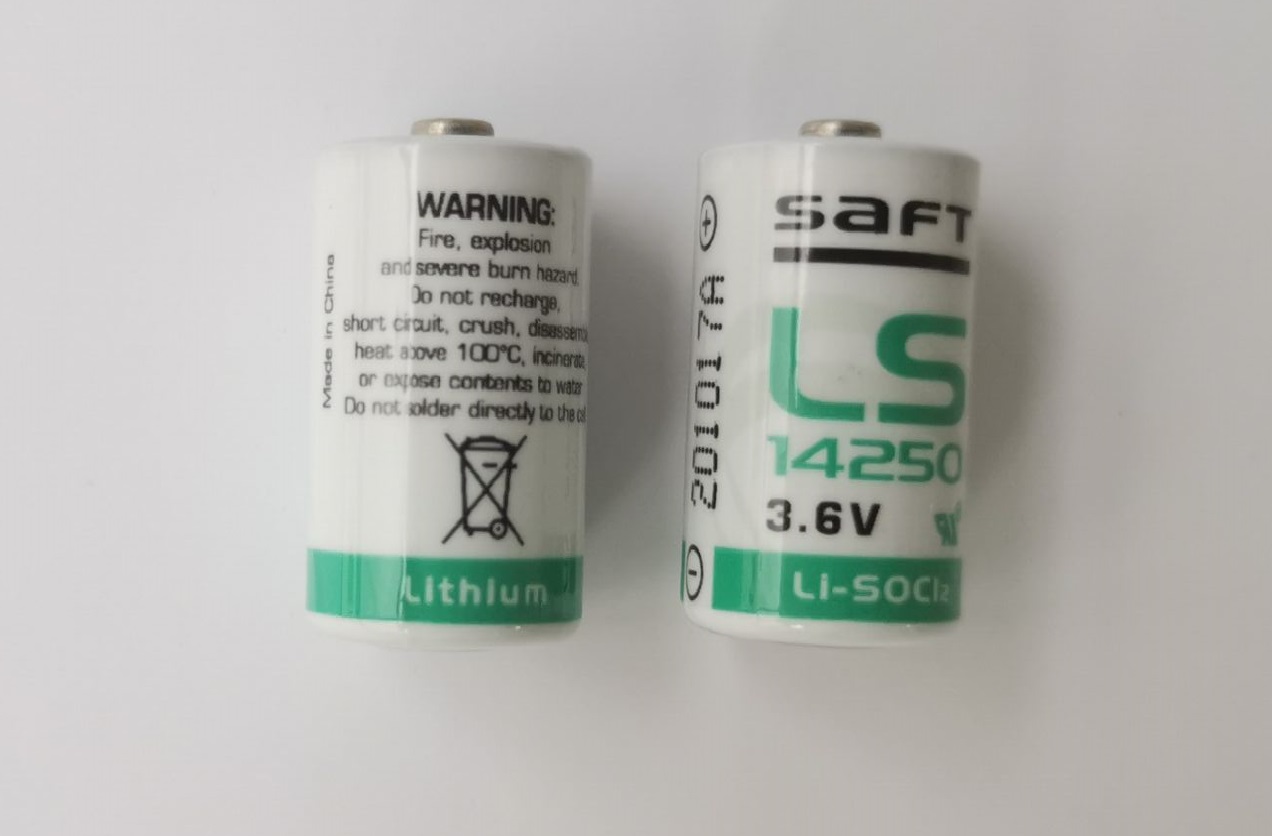

| type of battery | 2x lithium battery 14250 | |

| battery life | Standby | >600 days |

| 5% use | >540 days | |

| continue use | >360 days | |

| Sealing | IP68 | |

| Operating temperature | 0-60℃ | |

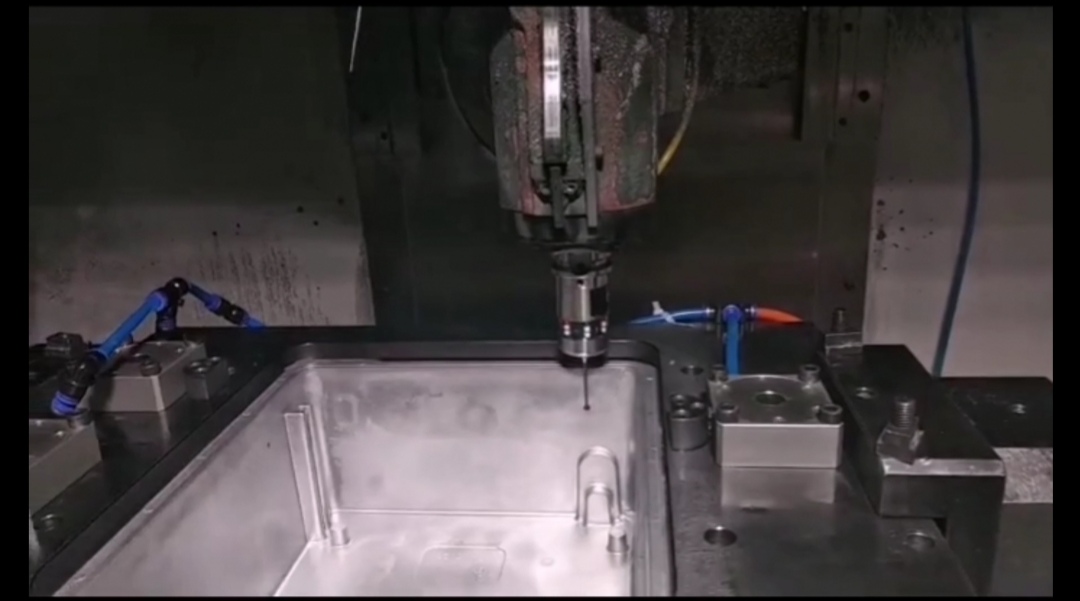

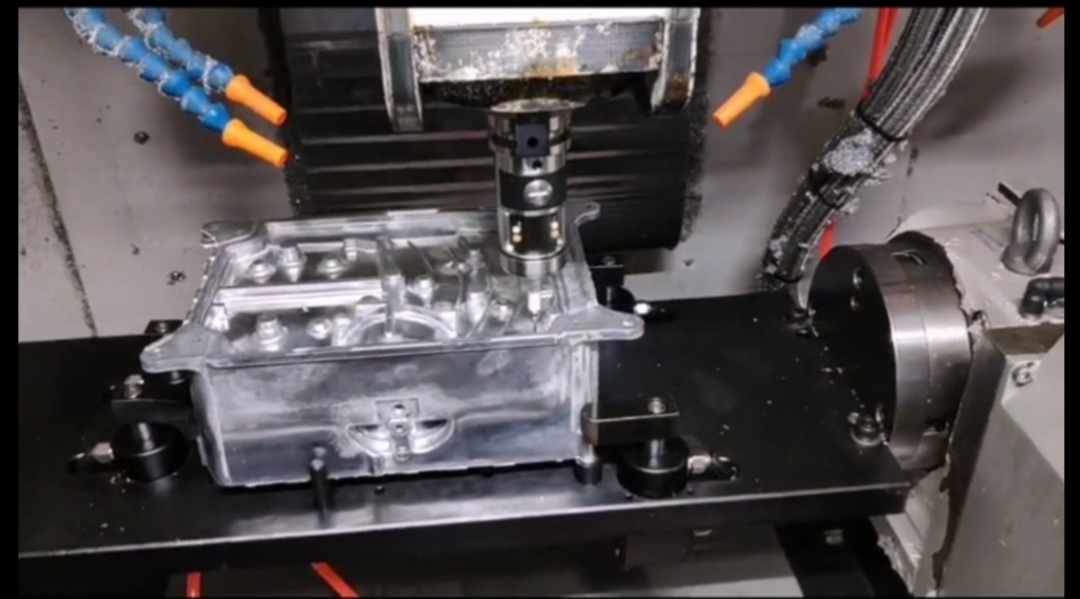

The radio wave touch probe can be used for the most varied measurement, and have widely used in various industries of machining:

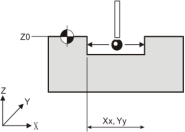

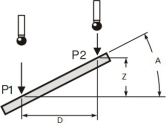

Measurement of standard

measurement the planeness , distances, angles, diameter measurement of inner holen, outside diameters, inside and outside widths on a manufactured workpiece

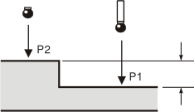

Workpiece inspection and position control

Fixture and product materials are often inconsistent, measuring the workpiece the results and errors are stored in a macro variable list. work offsets can be updated for accurate component positioning

Application case:

A standard touch probe contains the following 8 kinds of accessories, which can be used directly after installation and debugging no need to purchase additional accessories, list:

probe , 1 piece, standard

reciver, 1 piece, standard

stylus, 1 piece, stankared is φ2*50 flat stylus

battery, 2 piece, SaFT 14250

tool holder, 1 piece, The standard is BT30 and BT40, If it is other spindle, please confirm with the sales

pull stud, 1 piece , match with tool holder

Magnetic base, 1 piece , standard

spanner, 2 piece , for adjust the screw

About software and programs:

To measure 2D dimensions, no additional software is required, only a program needs to be written

We can provide macro program templates. If you have experience in using Renishaw , blum and marposs probes, you can also use their programs directly. Because the programs are basically universal, just need to change a few parameters.

CNC controler and machine tool we have successfully installed include: Mitsubishi, FANUC, brothers, Siemens, heidenhain, FAG, Haas, Mazak, Makino, DMG, Doosan and so on

About hardware:

■ Confirm the type of probe according to the characteristics of the parts to be machining, infrared or radio transmission.

we recommended to select infrared for small parts and radio transmission for large cavity parts to prevent unstable signal transmission caused by obstacles

■ Confirm the model of the spindle in order to select the correct tool handle

■ Confirm the form and specification of the measuring stylus

■ Confirm whether the battery is needed, because there are restrictions on the battery during international express delivery or customs clearance

Installation, maintenance and training

The installation of probe is complex, which needs to write macro program, and different from NC controler systems. Therefore, if you have no experience in using the probe, you will have a lot of trouble. We prefer to cooperate with dealers. If you are an end user, please confirm that there are technicians who install and use the probe, such as renishaw, blum, marposs, metrol.

For the specifications, installation manual and macro program of the probe, please go to the designated place to download document or contact the sales department