Self centering vise

High Quality & Affordable Self-Centering Vise China Supplier & Manufacturer - SILVERCNC

■ Centering repeatability < 0.015mm,

The Left- and Right- handed leadscrew positions your workpiece in the center of the vise with exceptional accuracy

■ Simple Design

Quickly reverse jaws / change jaws on the fly. Our simple bolt-on jaw design eliminates the need to take apart the vise to change jaws.

■ Made for Soft Jaws

Quickly remove the standard hard jaws and replace them with machinable jaws. Soft jaws are used for secondary operations + finishing work.

■ Reasonable price

Because of the low labor cost and operating cost of manufacturing in China, it has a great advantage in price, which is generally half prcie of other brands.

Self centering vise Benefits and features

1. Self centering vise have strong clamping force, compact design, high repeatability accuracy and stability, more and more machinists begin to like it.

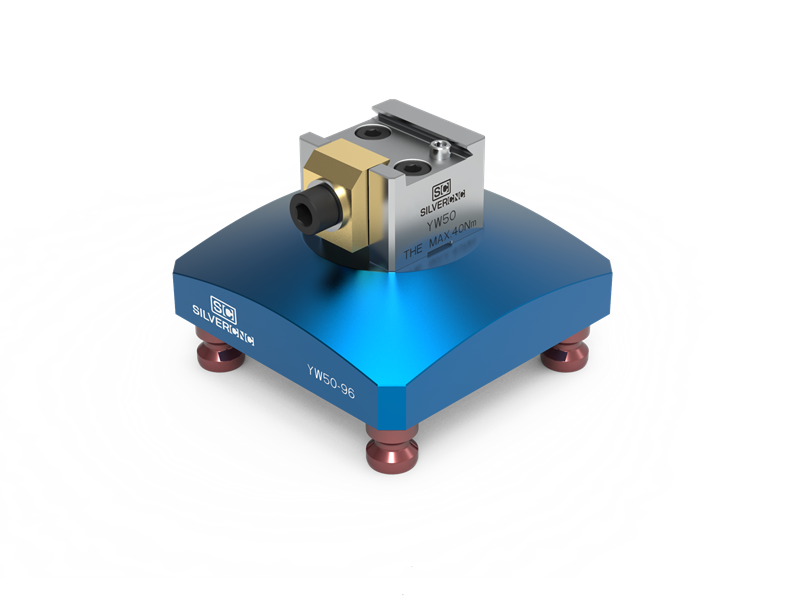

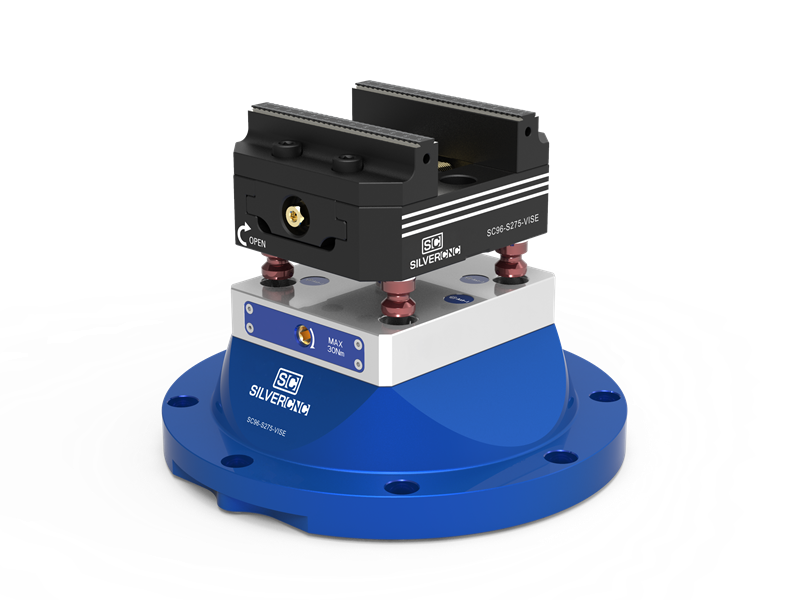

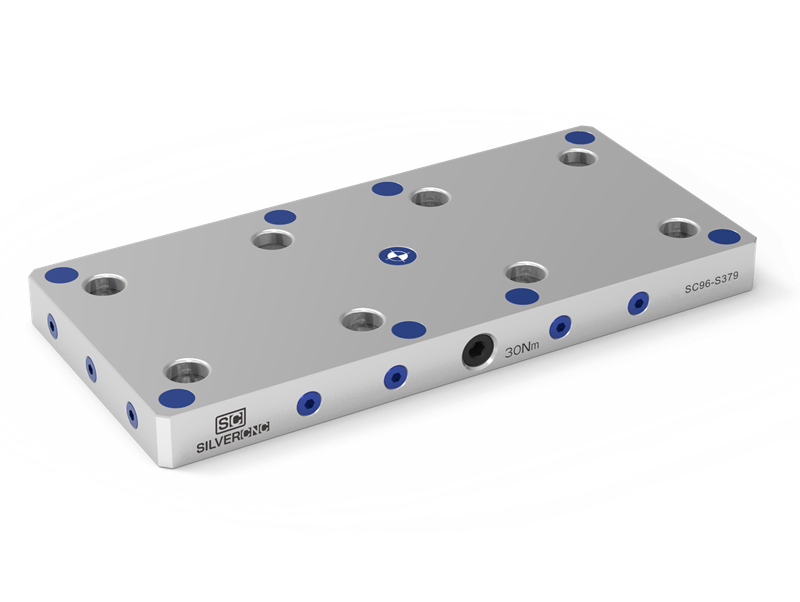

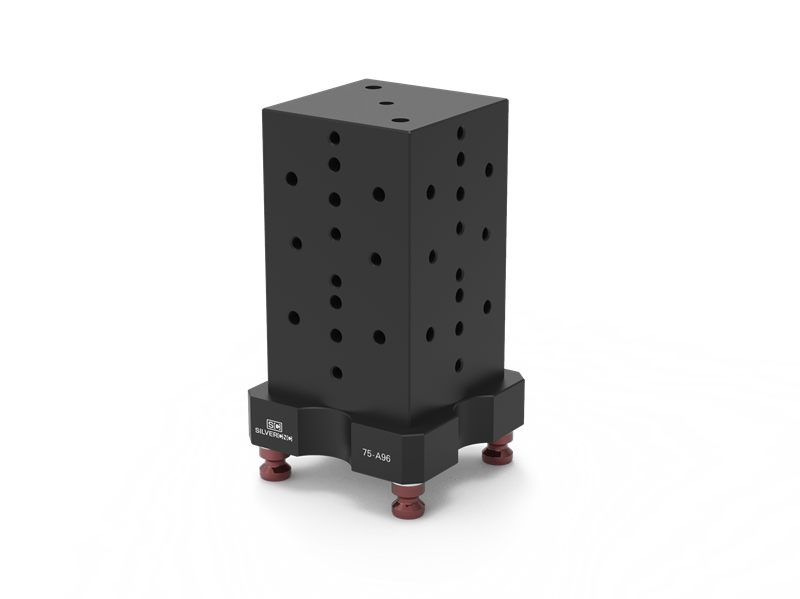

2. Matched with the zero point base plate, universal with 52 and 96 type stud, to improve clamping efficiency.

3. Forward,reversible, dovetail , quick change jaws,Suitable for various parts, light cutting and heavy cutting machining.

4. Low Profile, Small Footprint, 5 axis self centering vises are highly compact; easily reach five sides of the workpiece, even for oddly-shaped parts

SILVERCNC Self Centering Vise Specifications

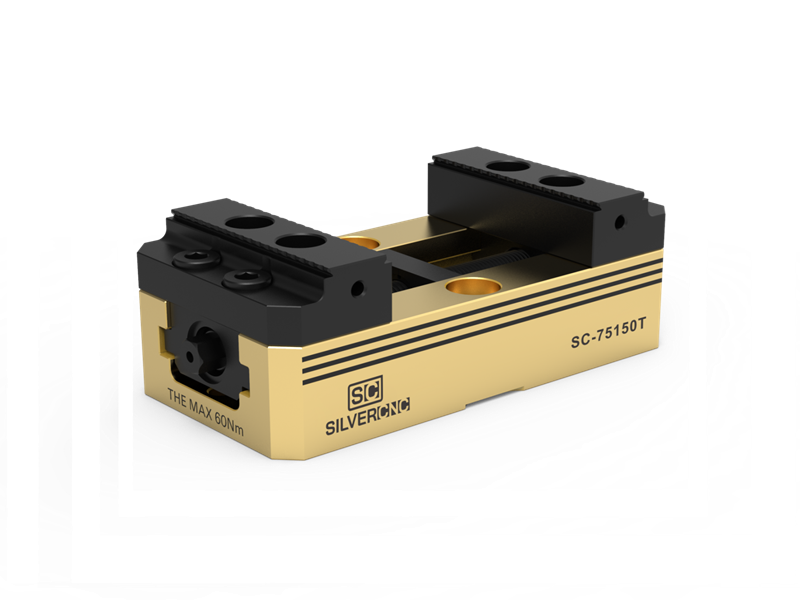

1. small size vise: SC-75100, SC-75150

SC-75100 and SC-75150 are small size vise. They are suitable for clamping small products and can be used with 52 type four hole zero point base to realize rapid clamping and positioning and improve production efficiency.

2. Medium size vise: SC-128128, SC-130155

SC-130155 and SC125-128 are medium size self centering vise, they are the most widely used and are most loved by the majority of users. It can be used with 96 type four hole zero point base, which is more convenient and fast, and can quickly improve the production efficiency.

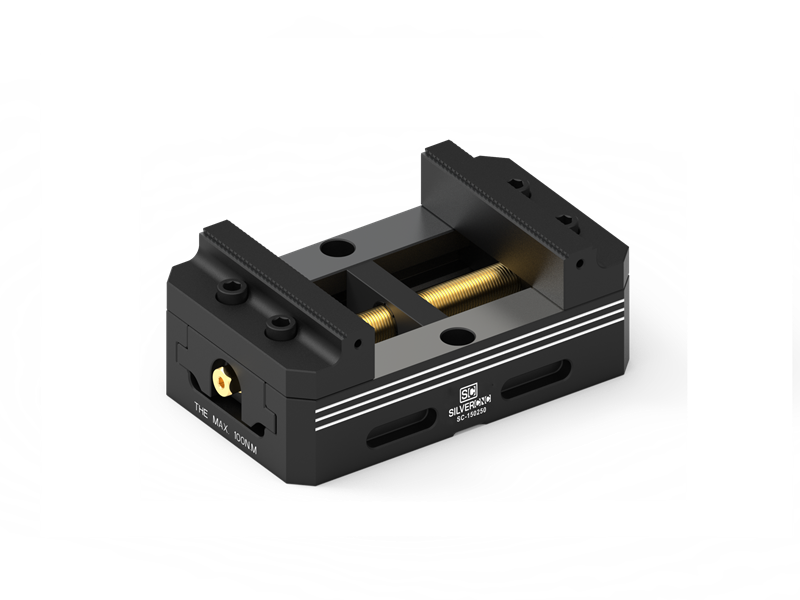

3. Large size centering vice: SC-130250, SC-150250

SC-130250 and SC-150250 are large size self centering vise, they are used for clamping large parts. It can be used with 96 type four hole zero point base, which is more convenient and fast, and can quickly improve the production efficiency

Model | SC-75100 | SC-75150 | SC-125128 | SC-130155 | SC-130250 | SC-150250 |

Dimessions/mm | 75*100*56 | 75*150*56 | 125*128*73.5 | 130*155*73.5 | 130*250*73.5 | 150*250*94 |

Repeatability/mm | 0.01 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

Clamping range/mm | 0-77 | 0-121 | 0-128 | 0-150 | 0-240 | 0-240 |

width/mm | 75 | 75 | 125 | 130 | 130 | 150 |

maximum torque/N.m | 60 | 60 | 75 | 75 | 75 | 100 |

Weight | 2.5 | 3 | 6 | 7 | 9 | 16 |

Self Centering Vise Mechanism

Why Choose SILVERCNC?

Affordable Prices

As a direct manufacturer, we eliminate middlemen, passing on significant savings to our customers without compromising on quality.

Fast Delivery

Time is of the essence in manufacturing, and we ensure quick turnaround times with fast, reliable delivery to keep your operations running smoothly.

Custom & Diverse Options

We understand that each project is unique, which is why we offer customization options to meet your specific requirements. Our range of diverse solutions ensures that we have the right fit for every need.

High Quality

We pride ourselves on delivering products that meet the highest standards of precision and durability. Every product undergoes strict quality control to ensure top-notch performance.

Related Products

FREQUENT ASKED QUESTIONS (FAQS)

A self centering vise is a tool used in machining that automatically centers the workpiece in the jaws as they close. Unlike traditional vises, where the user has to manually adjust the workpiece, a self-centering vise eliminates the need for manual alignment. It is commonly used in CNC machines, lathes, and milling machines, where precision and quick setups are essential.

This vise is particularly useful for holding parts of different shapes and sizes, offering a reliable and efficient solution for machining tasks that require consistent results.

A self centering vise automatically aligns the workpiece in the center of its jaws when the vise is tightened. The vise features two jaws that move simultaneously in opposite directions to grip the workpiece evenly. As the jaws close, they adjust to the workpiece’s shape, ensuring that it is centered without requiring manual alignment. This mechanism saves time and improves precision, making it ideal for tasks that demand consistent positioning, such as CNC machining.

In summary, the self-centering vise uses a simple yet effective design that automates the alignment process, providing both speed and accuracy for various machining operations.

When choosing a self-centering vise, consider the following factors to ensure you pick the right one for your needs:

- Workpiece Size: Make sure the vise can accommodate the size and shape of the workpieces you plan to use.

- Jaw Material: Opt for durable materials such as hardened steel or stainless steel for long-lasting performance.

- Jaw Type: Some self-centering vises have interchangeable or adjustable jaws for versatility, allowing you to work with different part shapes.

- Clamping Force: Choose a vise that offers enough clamping force to hold the workpiece securely without causing damage.

- Compatibility: Ensure the vise is compatible with your machine, whether it’s a CNC, lathe, or milling machine.

By considering these factors, you can select a vise that improves the efficiency and accuracy of your machining operations.

A self-centering vise offers several advantages for CNC machining:

- Precision: Automatically centers the workpiece, reducing the risk of errors and improving machining accuracy.

- Faster Setup: Saves time during setup as there’s no need to manually align the workpiece. This is especially helpful in high-volume production.

- Reduced Risk of Damage: The vise applies even pressure, minimizing the risk of distorting or damaging delicate parts.

- Consistency: Ensures consistent alignment for each workpiece, which is essential for producing identical parts in mass production.

- Ease of Use: Simple operation, even for less experienced machinists, due to the automatic centering feature.

Overall, a self-centering vise increases efficiency, precision, and consistency, making it a valuable tool for CNC machining.