Manual Tailstock

High Quality Manual Tailstock From China Manufacturer - SILVERCNC

SilverCNC is a direct manufacturer known for delivering high-quality, precision manual tailstocks that enhance operational efficiency. Our CNC tailstock is a reliable and essential component, ensuring stable operation, improved productivity, and exceptional results for your machining needs.

Features of Our Tailstock

- Easy installation and maintenance

- Extra stability for heavy cutting applications

- Clamp handle can be customized on left or right side

- Optional pneumatic or hydraulic brakes for improved control

- Longer workpieces support

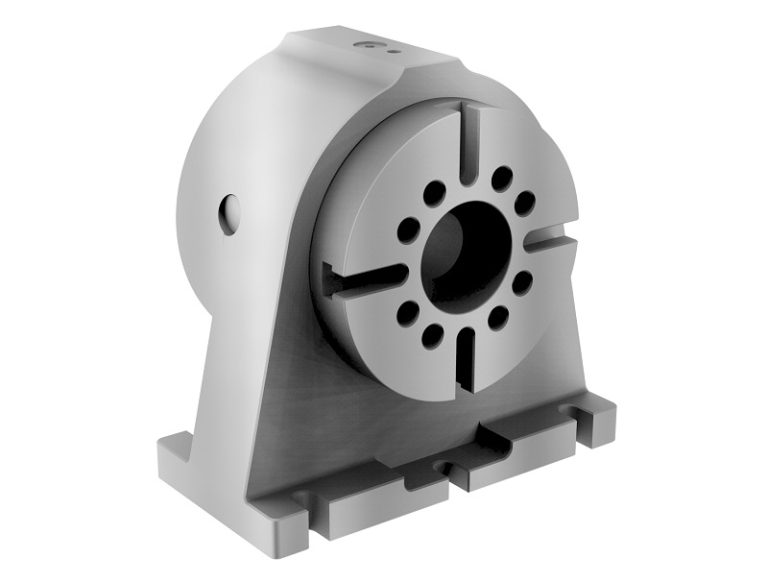

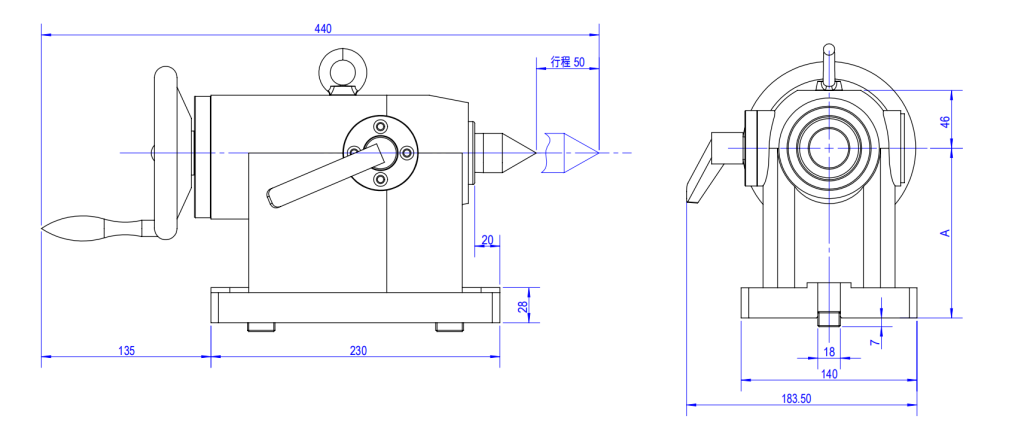

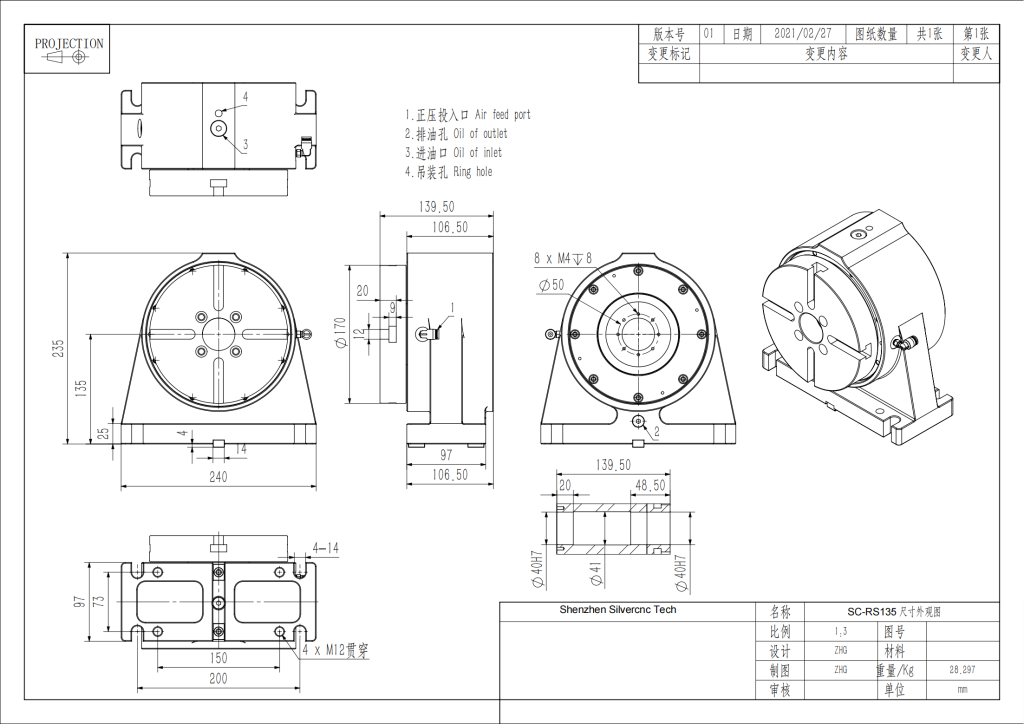

Descriptions of CNC Machine Lathe Tailstock

A tailstock is a crucial component found in lathes and other machining equipment, positioned opposite the headstock to provide support for the workpiece during machining, particularly for longer or cylindrical parts. The lathe tailstock helps to stabilize the non-driven end of the workpiece, ensuring it remains centered and secure during turning, drilling, and tapping processes.

The tailstock is often used in combination with a bridge plate and a 4th axis rotary table on the opposite side. It can be equipped with either a pneumatic or hydraulic brake for added stability. The tailstock’s center height is designed to be consistent with the rotary table, and there are four available specifications: 135, 150, 160, and 210.

Specifications of Our Manual Tailstock

Models | A/mm | Weight/Kg | Matching rotary table model |

RD-135 | 135 | 23 | C170 |

RD-150 | 150 | 25 | C180 |

RD-160 | 160 | 26 | C200/C250 |

RD-210 | 210 | 30 | C255/C320 |

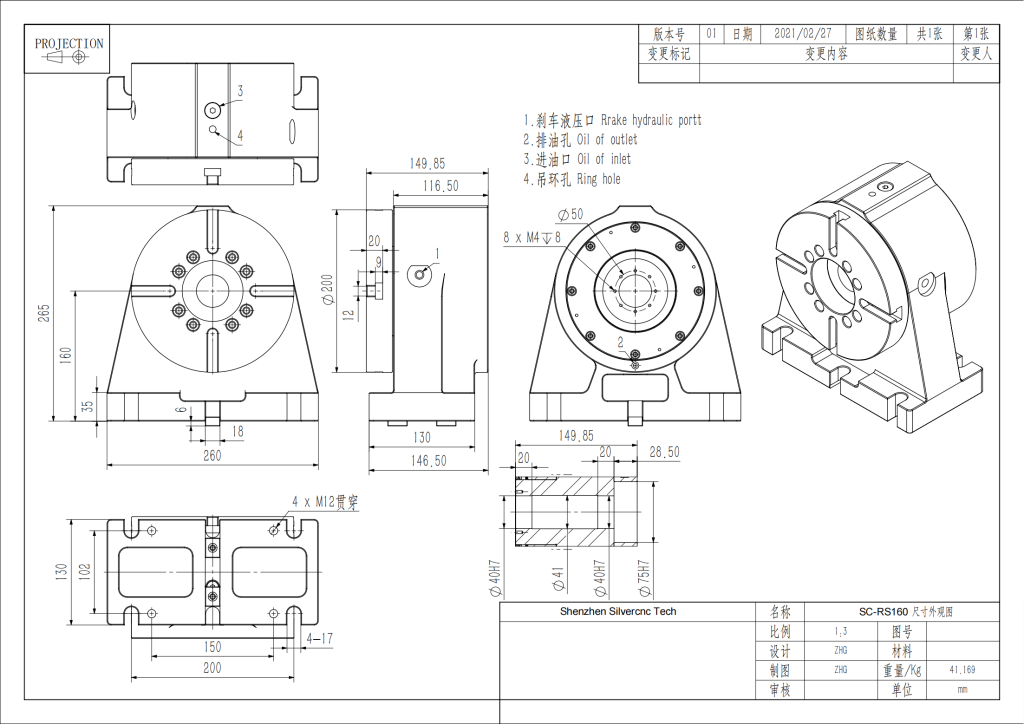

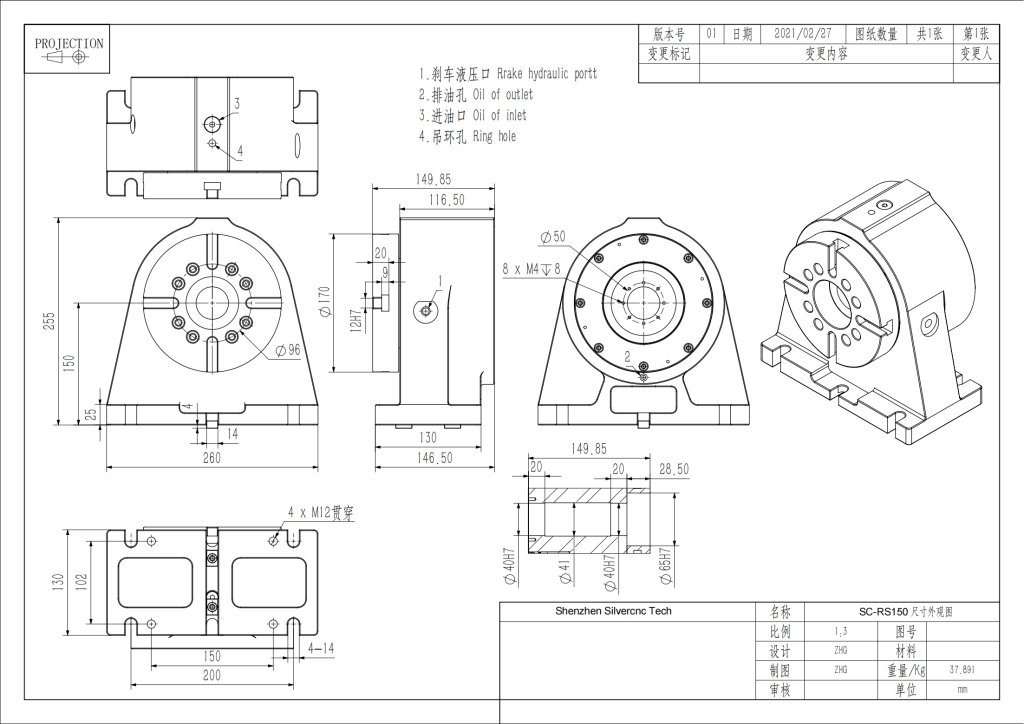

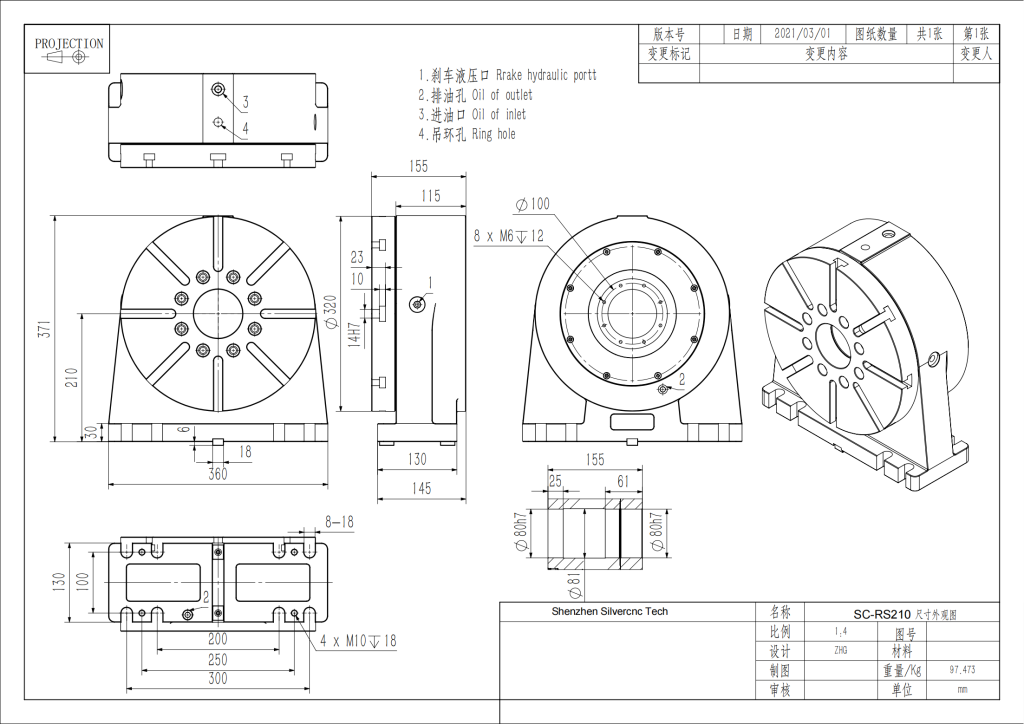

SILVERCNC Manual Tailstock Assembly Diagram

This tailstock diagram provides a detailed visual representation of the various tailstock assembly. It typically includes components such as the base, sleeve, spindle, and quill, which are crucial for proper operation.

SC-RS170

SC-RS200(250)

SC-RS180

SC-RS255(320)

The Importance of Using a Tailstock

The tailstock is used in machining operations, particularly on lathe machines, for several important reasons

Support for the Workpiece: The primary function of the tailstock is to provide support to the workpiece during turning or other machining processes. It helps prevent the workpiece from bending or deflecting as it rotates, especially for longer or slender parts.

Centering and Alignment: The tailstock often holds a live center or a dead center, which helps maintain the alignment and stability of the workpiece. This ensures that the workpiece remains centered as it rotates, which is crucial for producing accurate parts.

Facilitates Drilling, Reaming, and Tapping: The tailstock can be used to support tools like drills, reamers, or taps. When performing operations such as drilling or tapping, the tailstock helps ensure the tool is aligned correctly with the workpiece, improving accuracy and reducing wear on the tools.

Increased Precision: By providing additional support, the tailstock allows for more precise machining. It reduces the chances of vibration, deflection, or misalignment, which can lead to errors in the finished part.

Applications of Manual Rotary Table Tailstock

The manual tailstock is generally used with L block, connecting plate, chuck, hydraulic station and other accessories.

Please note that it must be consistent with the center height of the four axis rotary table.

A tailstock is an essential component of a lathe machine, used to support the workpiece, especially when it is being turned or machined. It is positioned opposite the headstock. Lathe tailstock provides additional stability and support for longer or more delicate materials during operations like drilling, reaming, or tapping. The tailstock helps maintain accuracy and precision, ensuring the workpiece remains securely fixed in place.

There are several types of tailstocks used in machining operations, each designed for specific functions and requirements. Here are the main types:

Fixed Tailstock: This is the most common type, where the tailstock is securely fixed to the bed of the lathe and cannot be moved along the machine’s axis. It provides stable support for workpieces, typically used for smaller, standard operations.

Movable or Sliding Tailstock: This type can be adjusted along the length of the lathe to accommodate different workpiece sizes. It provides flexibility and is commonly used in tasks where varying workpiece lengths are involved.

Turret Tailstock: A turret tailstock features a rotating turret mechanism, allowing multiple tools or centers to be mounted on the tailstock. This type is often used in more complex operations where multiple tool changes are required.

Self-Aligning Tailstock: This type includes a mechanism that automatically aligns the tailstock with the workpiece, ensuring that the workpiece remains centered during machining operations. It is especially useful for high-precision tasks.

Hydraulic Tailstock: A hydraulic tailstock uses hydraulic systems to apply pressure and adjust the tailstock’s position. This type provides more precise control and is often found in heavy-duty lathes and CNC machines.

In lathe machining, headstocks and tailstocks are both critical components, each with distinct functions that contribute to precision machining. The headstock holds and drives the workpiece, ensuring it rotates for tasks such as turning and facing.

Meanwhile, the tailstock provides support to the workpiece and holds tools for operations like drilling and reaming. Understanding the differences between these components is crucial for optimizing lathe machine performance and achieving high-precision results in industries such as metalworking, woodworking, and custom manufacturing.

The dead center in a lathe machine is a stationary component used to support the workpiece during machining. Positioned in the tailstock, the dead center helps to stabilize the workpiece, ensuring accuracy and precision in operations like turning, facing, and threading. Made from durable hardened steel, the dead center is essential for maintaining the integrity of the workpiece and preventing movement during machining. Unlike the live center, the dead center does not rotate.

No, the tailstock on a lathe does not spin. It is a stationary component that supports and stabilizes the workpiece during machining. This prevents unwanted movement that could affect machining quality. The tailstock can move along the bed of the lathe to fit different workpiece lengths. However, it does not rotate like the headstock or other rotating parts.