CNC Tombstone

High Quality CNC Tombstones from China Manufacturer

Precision Tombstone to fit several parts for many different operations into the same setup

CNC Tombstones are modular fixtures with bolt holes and dowel patterns on each face, allowing for quick and easy installation and removal of sub-plates and workholding components like manual or hydraulic vises.

This reduces setup time, increases machine running time, and improves the efficiency of clamping and disassembling parts.

1. Material: 6061-T6512 Aluminum

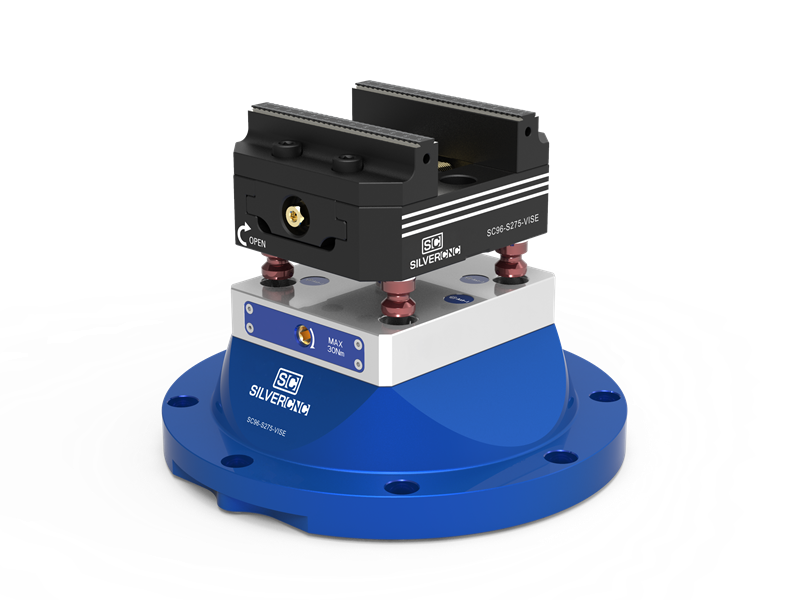

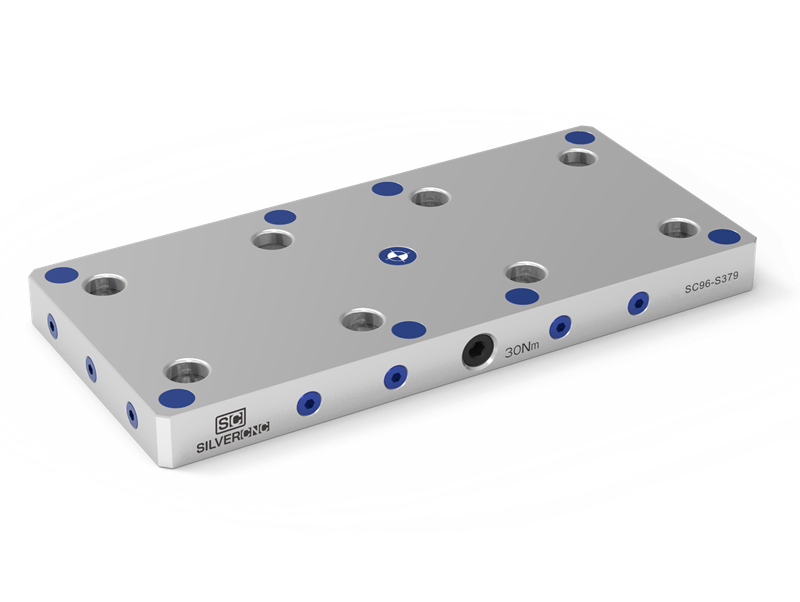

2. Compatible with zero point base plate, suitable for any 96mm base plate

3. Three sided and four sided tombstone available

4. Custom baseplates are available upon request

5. Each tombstone have 4pcs studs for free.

Custom CNC Tombstome Series From SILVERCNC

At SILVERCNC, we offer tailor-made CNC tombstones designed to meet your unique machining needs. Whether you require a 3-sided or 4-sided tombstone, we provide flexible solutions with the option to print your logo for a personalized design. Our custom tombstones help streamline CNC machining, improving efficiency and precision for your projects.

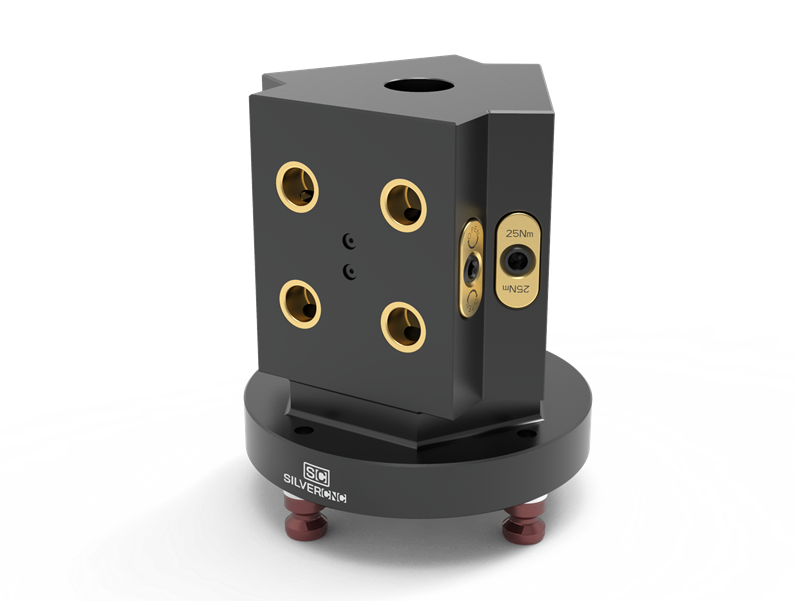

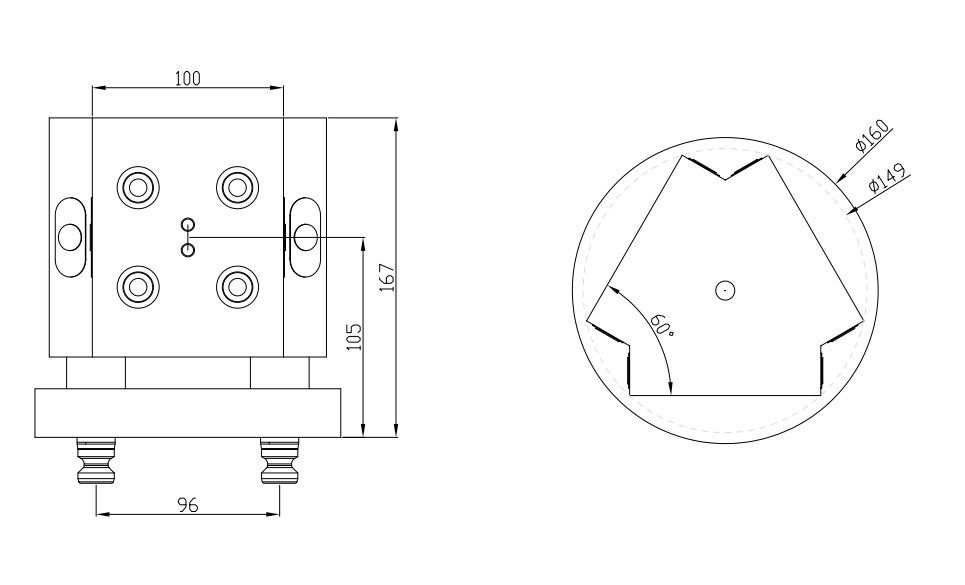

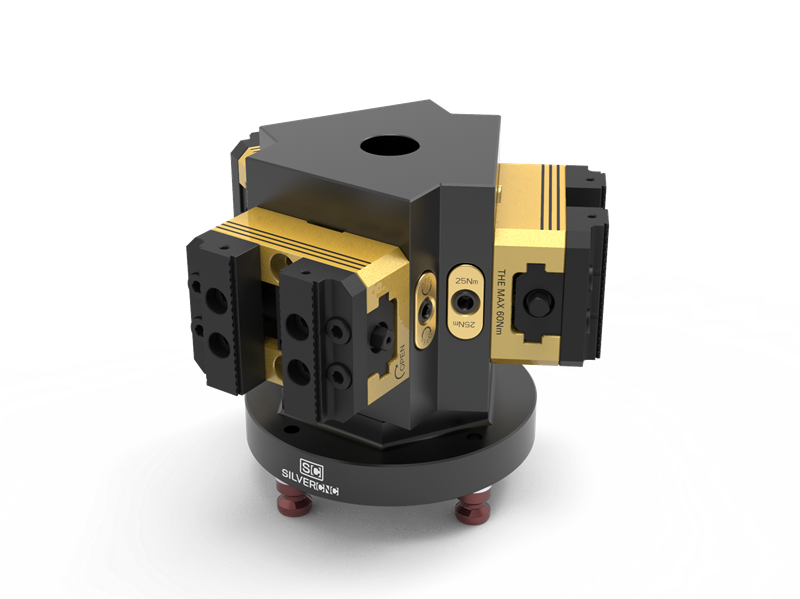

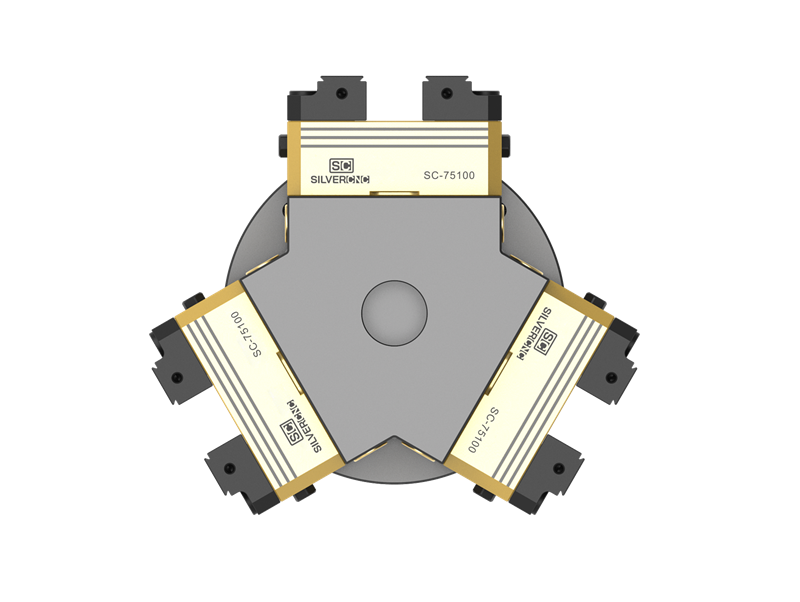

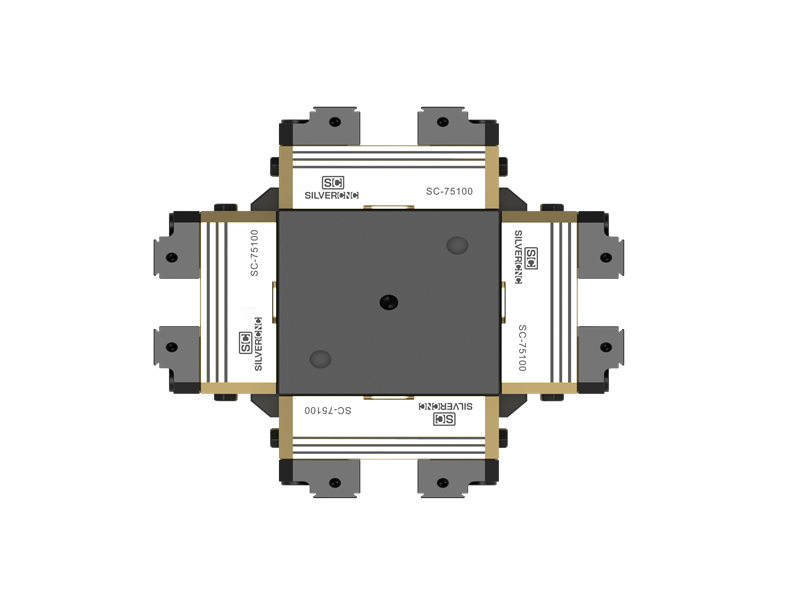

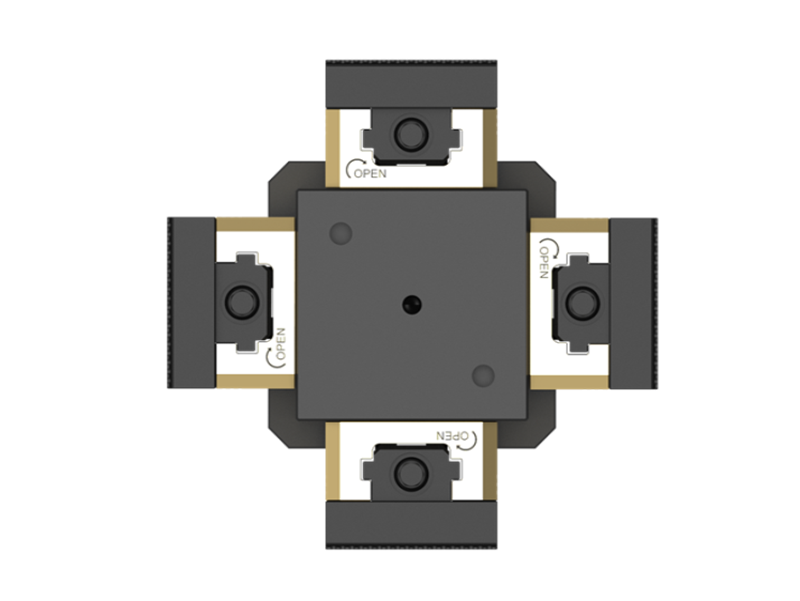

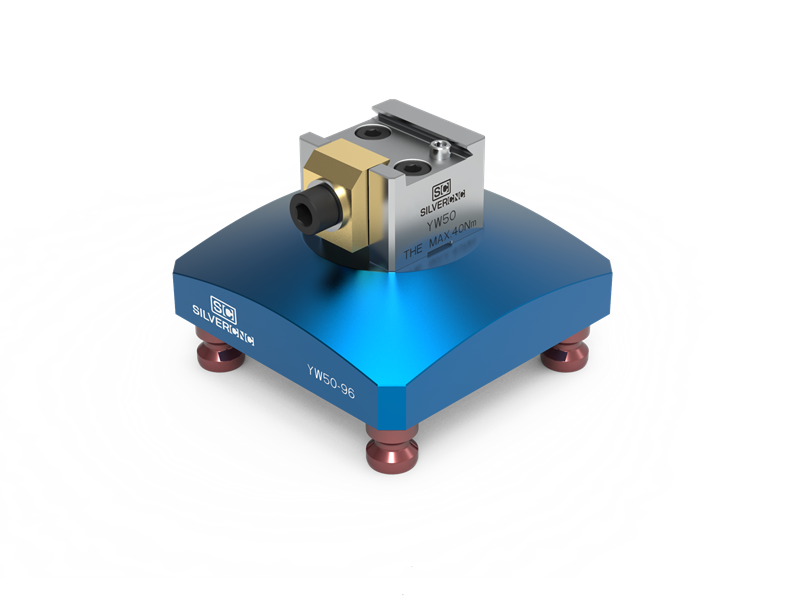

three-sided Integrated tombstone

- This three side tombstone integrates the 52 type zero pint base plate, the compact design can add 3 small size vise SC-75100.

- The unit features pull studs on the bottom so that it can be mounted onto any 96mm base plate.

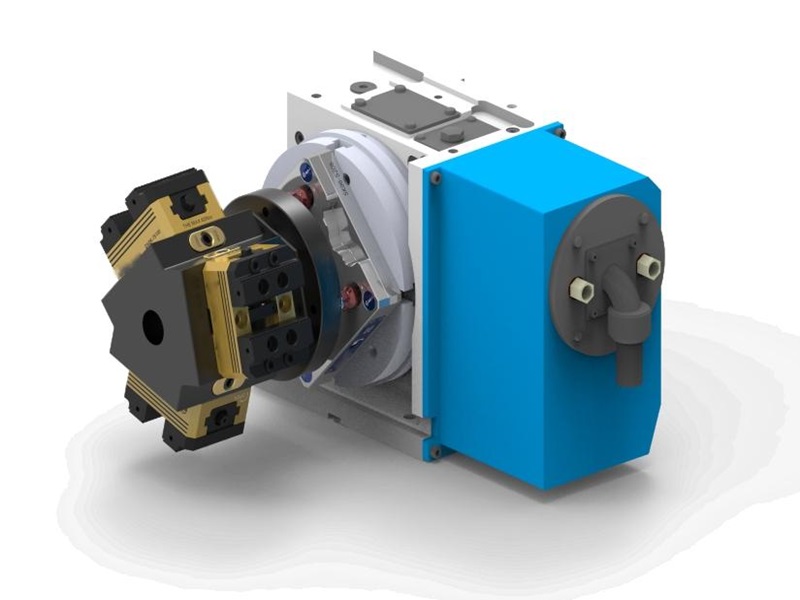

- It’s perfect fit for SilverCNC c170, C180 and C200 4th axis rotary table

- Three silverCNC sc-75150 self centering vise installed on the tombstone.

- The tombstone bottom 4 studs clamping the SC96-S190 base plate.

- The tombstone and base plate mounted on 200 4 axis rotary table.

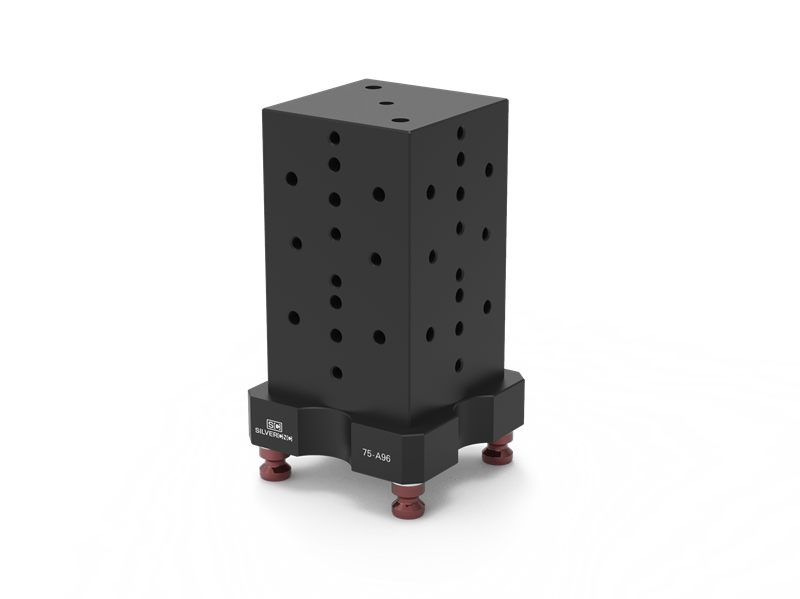

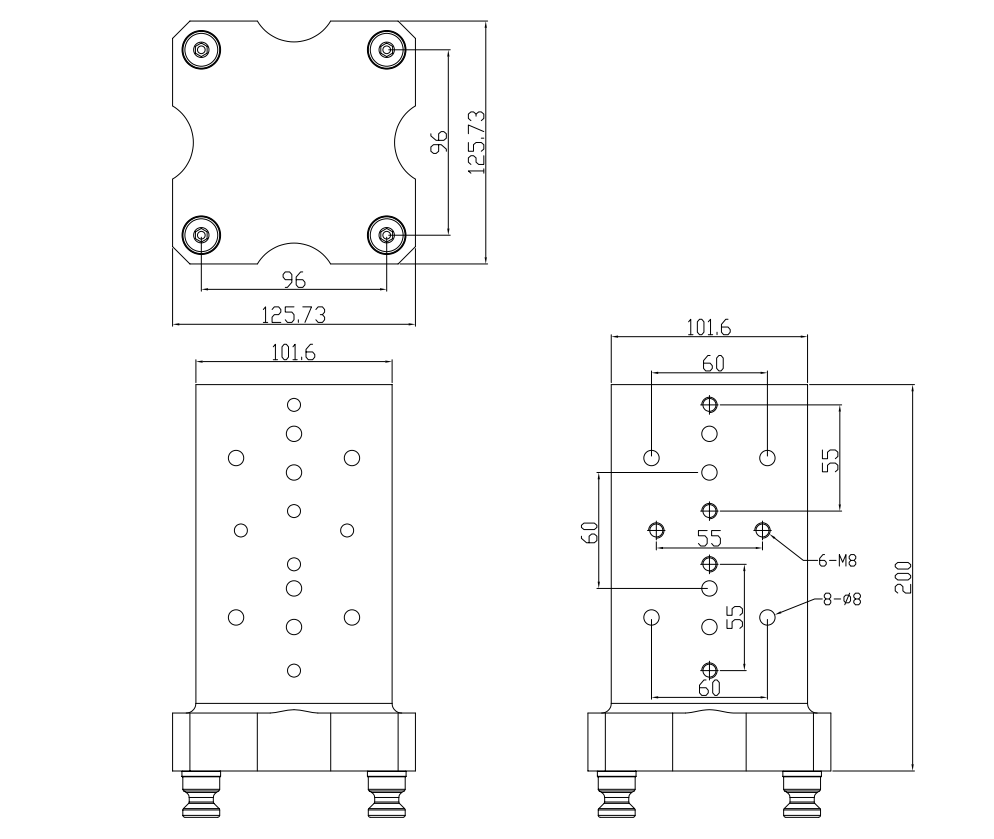

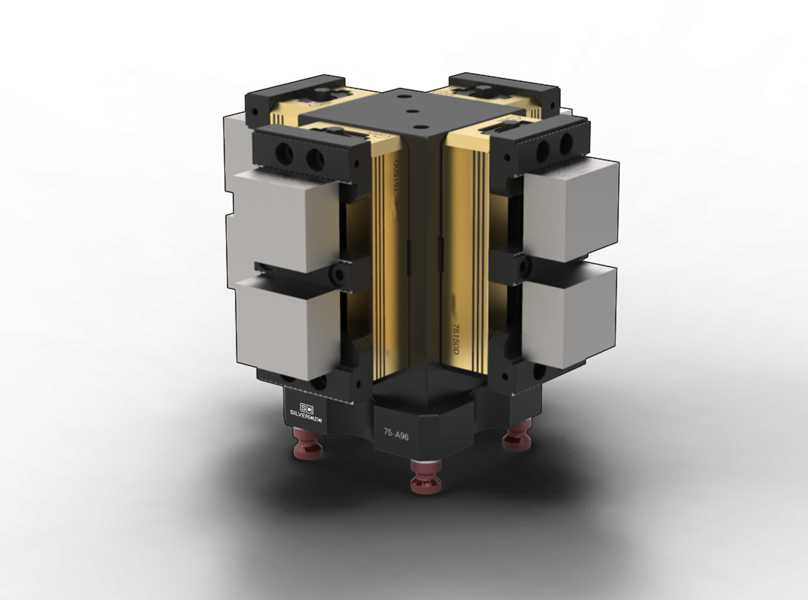

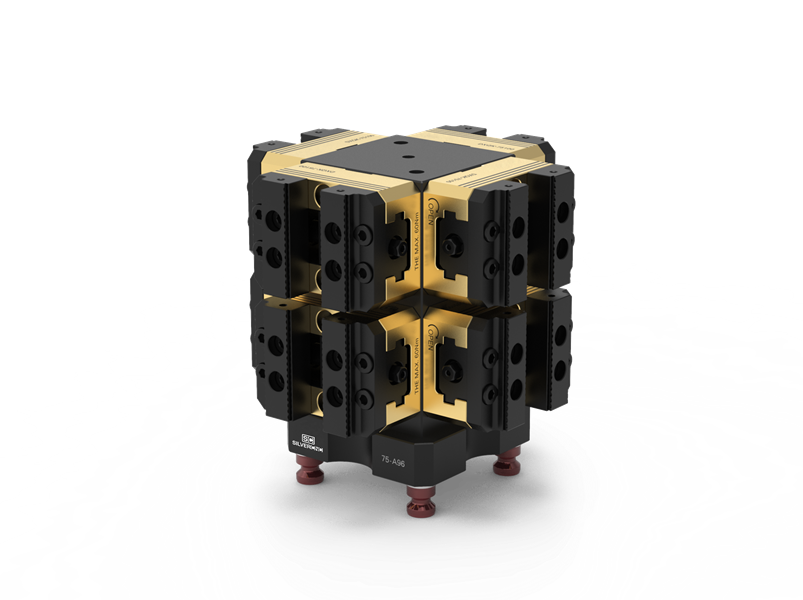

Four-sided Integrated Tombstone

- The 75-A96 is an ultra compact 4 sided mini tombstone designed to work with smaller 4 and 5 Axis machines.

- The tombstone can be mounted onto any 96mm zero point base plates. With a maximum of 12 vises on the tombstone, the machine can run unattended.

- It’s perfect fit for SilverCNC c170, C180 and C200 4th axis rotary table

- The vice can be installed vertically or horizontally

- The tombstone bottom 4 studs clamping the SC96-S190 base plate.

- Eight silverCNC sc-75100 self centering vise installed on the tombstone.

- Four pcs double station silverCNC sc-75150D self centering vise installed on the tombstone.

Why Choose SILVERCNC?

SILVERCNC offers a wide range of fixtures to precisely hold and position workpieces, enhancing CNC machining efficiency. Our zero point workholding solutions reduce setup time, ensuring quick and accurate part alignment.

With customizable options for complex parts, We deliver tailored solutions to meet diverse manufacturing needs. Made from durable materials, our fixtures guarantee reliability, boosting productivity and machining precision across various industries and applications.

Competitive Prices

Direct manufacturer pricing ensures cost efficiency.

Fast Delivery

Timely shipping to keep your projects on schedule.

Quick Response

Rapid support to address your needs and inquiries.

Patented Technology

Innovative, patented solutions that improve machining efficiency.

FAQs

1. What is a Tombstone in CNC?

A tombstone in CNC (Computer Numerical Control) machining is a critical fixture used to hold and position workpieces during the machining process. Its primary function is to securely hold multiple parts in place simultaneously, enabling multi-sided machining without the need for manual repositioning.

This efficiency significantly enhances productivity and reduces setup time, making it an invaluable tool in manufacturing environments.

2. Why is a Tombstone Used in CNC Machining?

A tombstone fixture maximizes the use of CNC machine tools by allowing operators to machine multiple sides of a workpiece or multiple parts in a single setup.

This leads to greater precision, higher throughput, and less downtime between operations. Additionally, it helps reduce the risk of human error when repositioning parts.

3. How Does a Tombstone Work in CNC Machining?

A CNC tombstone is typically made from sturdy materials like aluminum or steel. The workpiece is attached to the tombstone using clamps, bolts, or other securing methods.

Once secured, the CNC machine can execute a series of operations on various surfaces of the part by rotating the tombstone, allowing different orientations without manual intervention.

4. Key Benefits of Using a Tombstone in CNC Machining

- Increased Productivity: Machining multiple parts at once reduces the overall cycle time.

- Higher Precision: A stable fixture ensures accurate positioning of parts, minimizing errors.

- Reduced Downtime: Less frequent part repositioning and setup changes improve machine uptime.

- Optimized Use of Space: By holding multiple parts, tombstones maximize machine tool capacity, enabling continuous production.