Custom CNC Rotary Table index table From china Manufacturer & Supplier

SILVERCNC offers a wide range of precision rotary tables index tables and the accessories, enabling multi-axis machining with one-time clamping. This improves both efficiency and part accuracy.

Our products are widely used in VMCs and HMCs and are compatible with various CNC controller systems. Featuring a roller cam structure, they offer excellent wear resistance and long-lasting accuracy.

We guarantee high quality, competitive pricing, and fast delivery. OEM orders are also accepted.

- Roller cam structure ensures stable accuracy, long service life, and easy maintenance.

- Both 4th axis and 5th axis rotary tables are available.

- Choose between simultaneous or single-axis control, depending on your machine tool requirements.

- You can select just the body or opt for a complete rotary table solution, which includes the tailstock, manual chuck, motor, brake device, single-axis controller, and trunnion table.

- Competitive pricing due to China’s lower manufacturing costs.

- Customizable logos to meet the needs of agents worldwide.

- MOQ is just 1 set

High precision and Good Stability, High Rigidity and Durability

Rotary table index table is one of the most important components of CNC Machining. Multi axis machining can be realized by one-time clamping, which can improve the production efficiency and the accuracy of parts, as well as shorten the cycle times.

SILVERCNC‘s rotary indexing tables can match with different brands of control systems, such as Fanuc, Mitsubishi, Siemens . widely used in automotive, aerospace, mold, parts machining and other industries. The rotary table almost the same quality but half price than some Japanese brands.

We confirm that you will benefit if you use our products. welcome to inquire and quote.

SILVERCNC CNC Rotary Table Series

Our precision cnc rotary tables index table are designed for high-precision applications and offer two drive options: servo-driven, and direct drive, allowing you to choose the most suitable system for your specific needs.

They support multi-axis machining (4-axis and 5-axis), enabling complex part processing and improved efficiency. Additionally, with tilting and horizontal capabilities, they have versatile positioning to suit various machining configurations and ensure maximum flexibility in your operations.

5 Axis CNC Rotary Table

5 Axis cnc Tilting Rotary Table China Manufacturer For Multi-Axis Machining

Horizontal Rotary Table

High Strength Roller Cam Driver Rotary Table For Horizaontal Machining Center

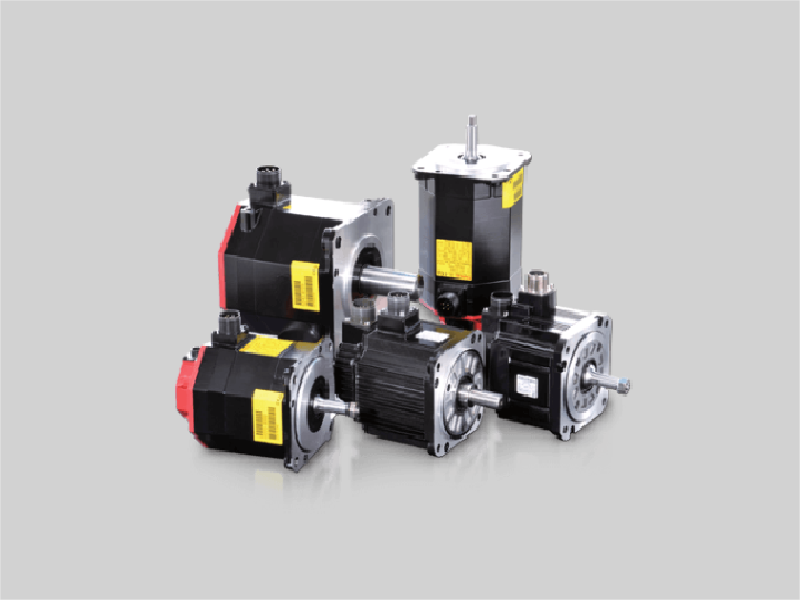

Rotary table servo motor

Different brands of servo motors for the corresponding various of CNC controllers

rotary table accessories

Manual chuck, Air to oil booster, Hydraulic booster, Encoder, L block

Rotary table single axis controller

Independent rotary table controller to achieve multi angle machining for no 4th axis function machine tool

Benefits of Using Rotary Indexing Tables

- Better Accuracy: They allow precise positioning, ensuring that each part is positioned exactly the same way every time, which is important for consistent results.

- Faster Production: They help speed up the process by automatically rotating the workpiece to the right position, cutting down on manual adjustments and setup time.

- Machining on Multiple Sides: With a rotary indexing table, you can machine several sides of a part in one go, saving time and reducing the risk of errors from repositioning the part.

- Versatile Use: They are flexible and can handle different types of workpieces and operations, making them useful for a variety of industries.

- Easy Automation: Rotary tables are easy to integrate into automated systems, making them ideal for high-volume or continuous production lines.

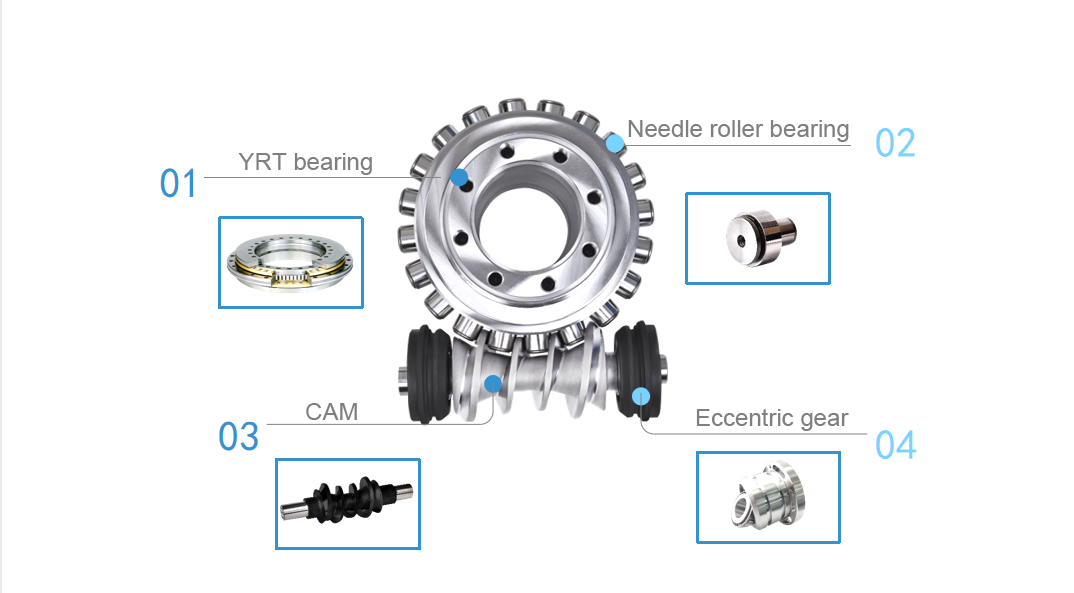

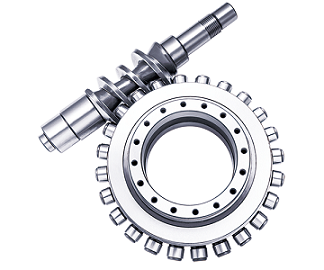

Zero Backlash Technology with Roller Cam Structure

Roller CAM Driver uses the roller gear mechanism. The unit is constructed from an input shaft(the roller gearcam) and a turret(output shaft)fited with roller folowers. The roller followers are preloaded against a screw-like input shaft to completely eliminate backlash. Our proprietary adjustment mechanism provides optimum preload. The roller folowers planted in the turrt which use internal roler bearings to transfer torque while rotating.

Why choose SILVERCNC's Rotary Tables For Milling Machines?

Roller CAM Driver Mechanism

We adapt roller cam driver structure, it always no backlash, high efficiency conduction, no thermal displacement, long working life, which has good brake performance compared with worm gear and DD motor rotary table

high Rigidity and Precise Rotary Motion

Our products utilizes a YRT bearing to provide exceptional rigidity and precision, combined with an innovative structural design, high-quality materials, and advanced machining processes to ensure a long working life.

Competitive Price

Our products offer exceptional value, providing the same specifications at nearly half the price of American brand – Haas Automation, making them a cost-effective choice without compromising quality.

High Quality Guarantee

Our products are built with stable, high-quality performance, requiring little to no maintenance for long-term reliability. Backed by a one-year warranty and readily available spare parts, they ensure a worry-free after-sales experience for customers.

Rotary Table mechanism

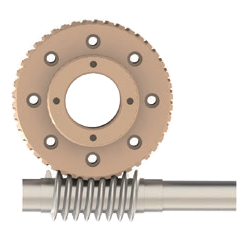

CNC Rotary table indexing table in the market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction of its mechanism:

It’s one of the most popular structrue because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

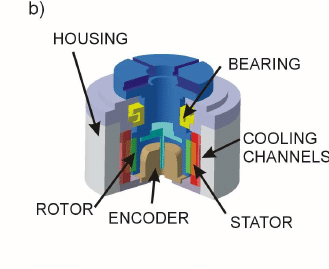

It’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price, and is generally used for five axis machine tools.

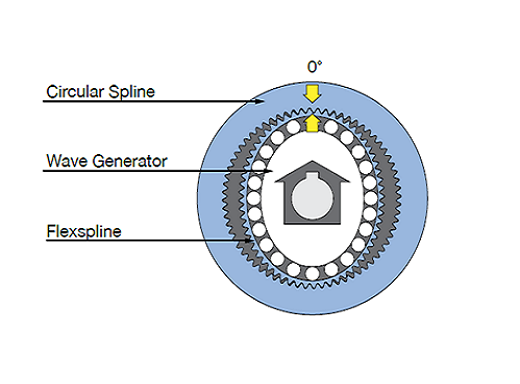

Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Worm Gear

Roller Cam

DD Motor

Harmonic Driver

Roller CAM VS worm gear

Item | Roller CAM Driver | Worm Gear Type |

Appearance | ||

Contact | rolling contact | Slide contact |

Material | hardening steel ,HRC60 | Hardening steel ,HRC60 |

Hardness of the contact part | bearing steel ,HRC60 | Phosphor broze,HB90 |

Preload | YES | NO |

Transmission efficiency | Good | Worse |

Backlash | Alway zero-backlash | Necessary for rub strock |

Indexing accuracy | Under 20 arc-sec | 12-20 arc-sec |

High speed possiblity | Fast | Slow |

Flipping time | 0.5sec | 1.5sec |

Heating possibility | Low | High |

Rigidity | High | Low |

Durability | Good | Worse |

Backlash adustment | Unnecessary | Necessary |

Expansion of 5th Axis | Yes | No |

Repair fees | Low(replace needle roller bearings) | High (Replace the worm gear |

Maintenance costs | Low(do not adust) | High(Adusted once a year) |

Downloadable PDF Resources for Rotary Indexing Tables

- Silvercnc rotary table catalogue

- 2D.3D-4th axis rotary table

- 5axis rotary table 3D models

- 5axis rotary table 2D drawing

- 2D.3D-H rotary table series

- Rotary table user manual

- Rotary table specification confirmation form

- Rotary table Packlist-EN

- Rotary table servo motors detail

- Rotary table tailstock specs

Frequent Asked Questions (FAQs)

A rotary table should be used in machining when precision and versatility are essential. It is particularly beneficial for operations requiring angular positioning, such as milling, drilling, or engraving complex shapes. If you’re working on parts that need multiple sides machined without repositioning, a rotary table allows for continuous work, enhancing efficiency. It’s also ideal for creating circular features, gears, and intricate patterns. Additionally, if you’re transitioning from manual to CNC machining, integrating a rotary table can facilitate multi-axis operations, making it a valuable tool for both hobbyists and professional machinists.

Rotary indexing tables operate by precisely positioning workpieces through controlled angular movements. These tables consist of a rotating platform that holds the workpiece and a drive mechanism that allows for accurate rotation to predetermined angles. When activated, the table rotates to the desired position and then pauses, allowing for machining or inspection tasks to be performed. The dwell time—how long the table remains stationary—is crucial for ensuring operations are completed accurately. Many modern indexing tables are automated and integrated with CNC systems, enabling high-speed operations with minimal human intervention while maintaining repeatability and precision.

A rotary table can typically turn 360 degrees continuously, allowing for full circular machining. However, many rotary tables are designed with specific indexing increments, often ranging from 1 to 90 degrees per step, depending on the application and design. Some advanced models can also perform continuous rotation beyond 360 degrees for complex machining tasks. The ability to set precise angles enhances flexibility in machining operations, making rotary tables suitable for various applications in industries like aerospace, automotive, and metalworking.