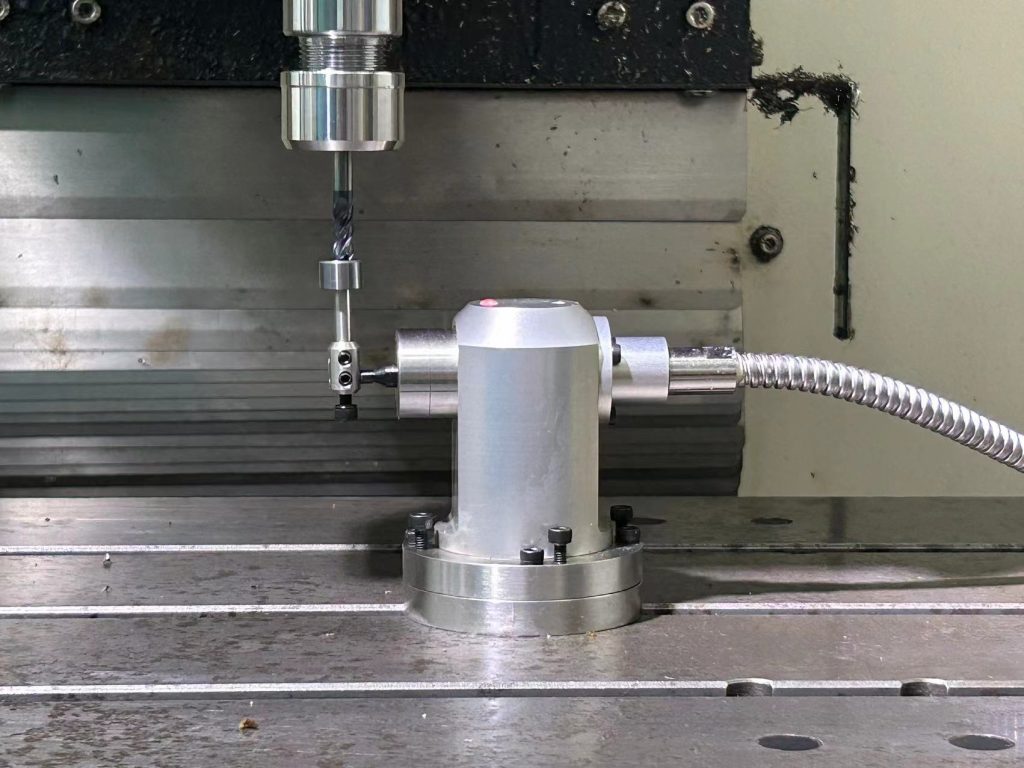

Affordable Non Contact Laser Tool Setter

Non-contact tool length and radius measurement as well as tool broken and breakage detection

SILVERCNC provideS a total solution of tool setters and tool breakage detection for CNC machining. We have designed a range of cnc tool setters including: laser control, contact type, optoelectronic signal trigger, all of these are used extensively in many industry

SILVERCNC offer three kinds of tool setter : laser measuring, length measurable , length and diameter measurable

Non-contact tool length and radius measurement as well as tool broken and breakage detection

Tool Setter For Tool Length And Radius Measurement And Tool Breakage Detection

The SOTS 3D touch trigger tool setter wireless infrared signal transmission, which can solve the problem of inconvenient cables

Tool Setting For CNC Machine Tool To Detect Tool Wear And Breakage

Have you ever face such a problem when machining: The preset tool length occupies a large part of the time. and when using small-diameter tools, there will be tool breakage, resulting in some defective products flowing into next process. How to solver? the tool setting can complete this task perfectly.

The tool setting can replace manual to measure the length and diameter of the tool and reduce the shutdown time of the machine tool. And it can detect the status of the tool regularly and feed back to the machine tool. When there are abnormal conditions, machine toos will stoped in time to prevent a large number of defective products. There is no doubt that each machine tools should be equipped with tool setter.

■ Saving CNC machine downtime and increasing reliability

■ Prevent defective products caused by tool breakage

■ Accurate tool length and diameter measurement,tool offset calculation and correction

■ High accuracy, high stability, repeatability is 0.001mm (Machine tool errors are not considered)

■ The warranty time is 1 years, spare parts are available, any problem will dealt with quickly by our after sales team

■ Reasonable price, compared with Renishaw , Blum, Marposs, Metrol brand

We provide overall tool detection solution, which can detect milling cutter, grinding head, grinding wheel, measuring tool length and diameter, tool breaking and damage alarm

We have a variety of products: from small engraving machines to large machining centers, contact and non-contact types, different principle,such as contact switch, photoelectric switch, kinematic resistant and laser control, to meet your machining requirements and budget completely.

| Contact tool setters model | Machine model | signal generation | Signal transmission | Minimum tool detection | Repeatability (2σ) | |

| M-P11/P21-10 | Small CNC Machining Centers | touch switch | Hard-wired | only tool length | Ø1.0 mm | 1.0 µm |

| M26D-20 | Small – large | touch switch | Hard-wired | only tool length | Ø1.0 mm | 1.0 µm |

| M-T24E-20/40/60 | large | touch switch | Hard-wired | only tool length | Ø1.0 mm | 1.0 µm |

| S5TS | Small – large | kinematic resistive | Hard-wired | tool length and diameter | Ø1.0 mm | 1.0 µm |

| SOTS | Small – large | kinematic resistive | Radio | tool length and diameter | Ø1.0 mm | 1.0 µm |

| SPTS20 | Small – large | Photoelectronic | Hard-wired | only tool length | Ø1.0 mm | 1.0 µm |

| Noncontact tool setters models | Machine model | signal generation | Signal transmission | tool setting | Minimum tool detection | Repeatability (2σ) |

| SNC86 | Small – large | laser | Hard-wired | tool length and diameter | Ø0.05 mm | ±1.0 µm |

1. What is a CNC Tool Setter?

A CNC tool setter is a device used in manufacturing to automatically measure and set tools in CNC (Computer Numerical Control) machines. It ensures that the tools used in the machine are the correct size, shape, and position before starting the production process. This tool setter helps increase efficiency by reducing manual errors and improving the accuracy of the machine’s operations.

2. What Does a CNC Tool Setter Do?

A CNC tool setter plays a crucial role in ensuring the CNC machine operates at its best. It measures the tool’s length, diameter, and position within the machine, ensuring these are set correctly before each cycle. The setter communicates with the CNC control system to adjust any settings if necessary.

The tool setter helps the machine quickly detect issues such as tool wear or breakage. By doing this, it reduces downtime and helps prevent defective parts from being produced, saving both time and money.

3. Why is Tool Setting Important?

Tool setting is vital because it ensures CNC machines operate with precision and accuracy. When tools are not properly set, it can lead to errors, poor-quality products, and costly reworks. Proper tool setting helps to avoid tool collisions, reduces wear, and ensures consistency across all products being made.

Additionally, good tool setting increases the lifespan of both the tools and the CNC machine itself. It allows for smoother, more reliable production, ensuring that every part is made to exact specifications, which boosts customer satisfaction and business efficiency.

4. Waht are the different types of CNC machine tool setters?

Manual Tool Setters

These require operators to manually measure and set the tools. While less automated, they are often more affordable and suitable for smaller operations.

Contact Tool Setters

Contact tool setter physically touches the tool to measure its length and diameter. It uses probes or mechanical arms to detect the tool’s position.

Non-Contact Tool Setters

Non-contact cnc tool setter uses laser or optical sensors to measure the tool without physical contact. It is highly accurate and prevent wear on the tool or setter.

Automatic Tool Setters

Integrated into CNC machines, these tool setters automatically measure and adjust tool positions during the machining process, reducing the need for manual intervention.

Tool Presetters

These are used outside the CNC machine to measure and store tool data (length, diameter, and breakage). The tool data is then loaded into the CNC machine to ensure precision during operation.

All products have been sold and used in large quantities, and all recognized by customers

Only 1/2 the price of some well-known brands.

Convenient and cheap to shipping

Hope to be your potential supplier, help to meet your diverse requirement