Infrared Touch Probe

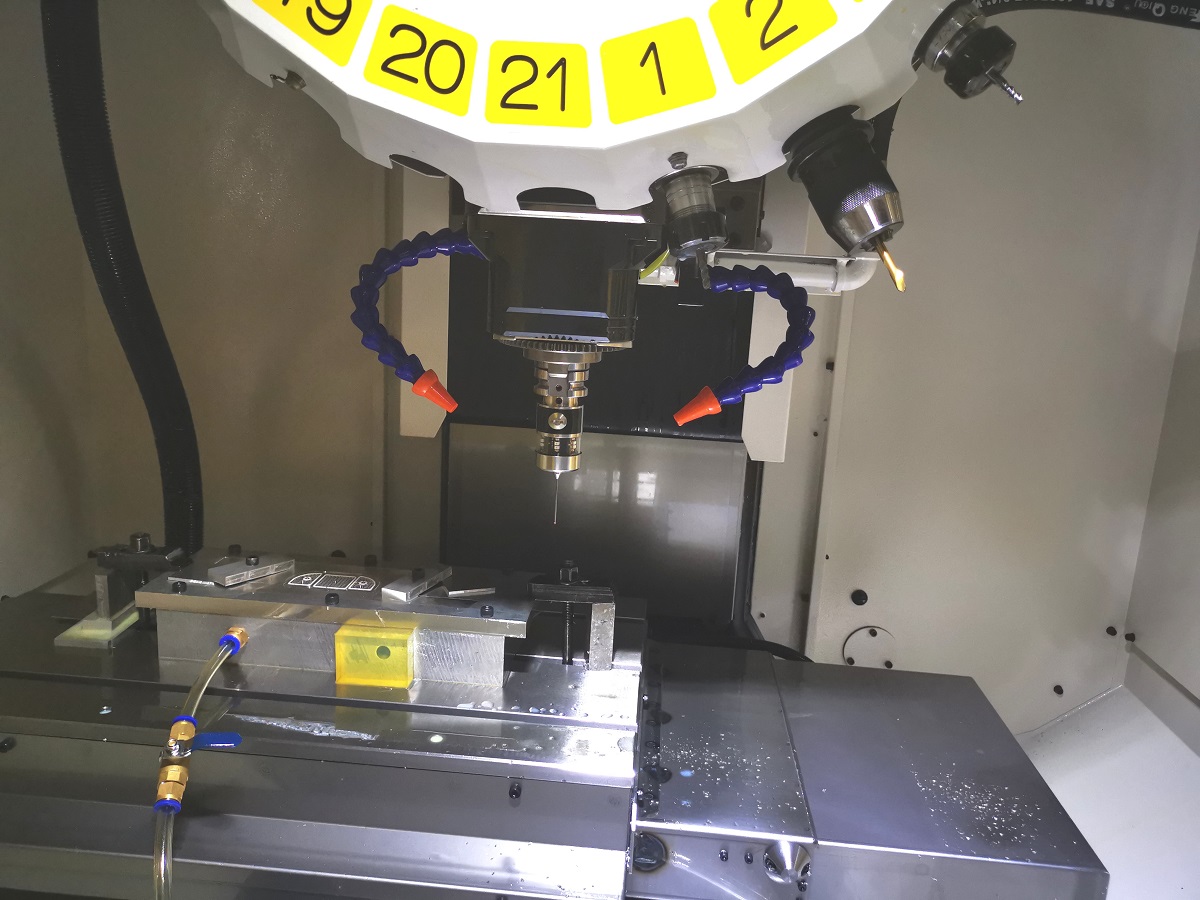

Infrared Transmission Touch Probes For Workpiece Measurement in Machine Tool

SILVERCNC is a competitive brand offering the best-selling touch probes for CNC machines in China and global market. Our probe features high precision, high quality, and good stability, with performance comparable to Renishaw, Blum, and Marposs. .

SILVERCNC‘s machien tool probes have been widely used across many industries in the Chinese market, with sales reaching 10,000 sets between 2019 and 2024, and earning recognition from customers. They are used to measure the size and position of workpieces, automatically correcting the offset of the tool or workpiece based on the measurement results. This helps improve the efficiency of your machine tool and the quality of your machined parts.

Infrared Transmission Touch Probes For Workpiece Measurement in Machine Tool

Radio Wave Triggered Transmissionl Touch Probes For Machine Tools

Wired Modular Touch Probing System Used In Lathe And High Gloss Machine

Styli For Machine Tool Touch Probes To Ensure Maximum Measurement Accuracy

CNC touch probe tool holder shank suitable for a whole range of spindle, compatible with Renishaw

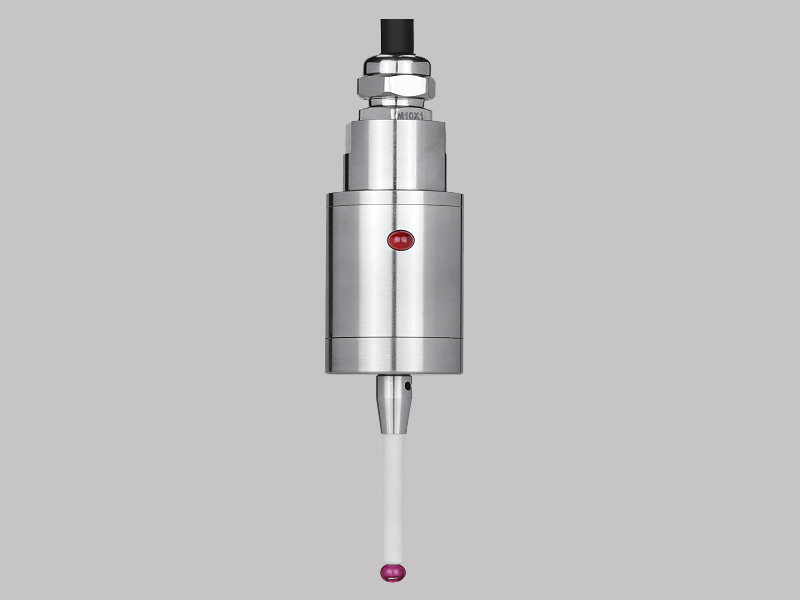

(1) Our machien tool probe uses a proven technology -kinematic resistive principle that can stably operate for long time,

(2) It can realize extremely precise measurements under standard 50mm probe styli at 600mm/min speed,

(3) The balls and rods of the probe adopt special process to ensure 10 million times life, to ensure excellent stability

(4)We has independently developed a micro-swing autonomous reset technology, successfully solving the issues of poor stability and inconsistent repeatability. Now, our probes offer excellent stability and high repeatability in positioning accuracy.

(1) We use coded signals optimized optical communication technology, to sure that the signal transmission is stable, response speed fast, and don’t lose signals.

(2) Our probe applies dual channel technology, through the remote control frequency change, perfect solve the problem of mutual interference of infrared probes in the industry, Innovation within probing industry.

(1) Our probe adopts the multi-threshold power consumption control technology, which greatly reduces the product power consumption, and by optimizing the chip design and circuit design, improves the battery life further.

(2) The use of our probe battery life is long, continue use >360 days, 5% use >540 days, Standby >600 days, Battery life is much higher than other brands

(1) The installation of the probe receiver is a troublesome job, which requires drilling holes in the machine tool for fixing.

(2) We designed a magnetic mounting base that allows the receiver to be mounted on the base and then attached together to the sheet metal of the machine tool, reducing installation difficulty.

| Type | Model | Quantity(PCS) |

| probe body | SOMP40/SRMP40 | 1 |

| tool holder | BT30/40/50 | 1 |

| receiver | standard | 1 |

| pull stud | BT30/40/50 | 1 |

| Magnet base | standard | 1 |

| battery | LS14250/pair | 1 |

| stylus | 2 * 50 Ruby | 1 |

Different brands of hardware are typically not compatible with one another. For example, Renishaw’s machine tool probes are designed to work only with Renishaw interfaces and cannot be directly replaced with hardware from us. However, Renishaw’s software and macro program package can be intergrated with our touch probes. Thus, you don’t need to change Renishaw’s macros when using our probes on a machine tool.

■ Set workpiece coordinates before machining to reduce the impact of fixture and incoming material errors

■ Improve machine tool manufacturing efficiency, reduce machine downtime awaiting first-off inspection results

■ High accuracy, high stability, repeatability is 0.001mm (Machine tool errors are not considered)

■ Long battery life (5 times as long as Renishaw)

■ The warranty time is 1.5 years, spare parts are available, any problem will dealt with quickly

■ Reasonable price, compared with the competitive brand has a larger advantage

Our probe is triggered by a pulse signal, which is normally open. When not in use, it automatically enters sleep mode and does not require an M code command to be closed. This helps reduce power consumption and significantly improves battery life.

Our probes can be compatible with tool setters. On turret machines, you can use two of our touch probes with just one receiver.

Model | Silvercnc/SOMP40 | Renishaw/OMP40-2 | ||

Unidirectional repeatability (Use standard 50mm probe at 600mm/min speed) | 1um (2σ) | 1um (2σ) | ||

Sense directions | ±X,±Y,+Z | ±X,±Y,+Z | ||

Stylus trigger force (Use standard 50mm probe) | XY plane 0.4 – 0.8N | Z direction 4.0N | XY 0.5,0.9N | Z 5.85N |

Trigger protection trip | XY plane +/-15° | Z direction 6.35mm | XY +/-15° | Z 6.35mm |

Signal transmission method | Optical transmission | Optical transmission | ||

Operating range | 5m | 5m | ||

Trigger life | >10 Million times | >10 Million times | ||

Transmission angle | 360 ° along the probe axis | 360 ° | ||

Transmission on/off style | smart switch | M code | ||

Weight without shank (including batteries) | 280g | 240g | ||

type of battery | 2x lithium battery 14250 | 2x lithium battery 14250 | ||

battery life | Standby | >600 days | Standby | >100 days |

5% use | >540 days | 5% use | >90 days | |

continue use | >360 days | continue use | >60 days | |

Sealing | IP68 | IP68 | ||

Operating temperature | 0-60℃ | 5-50℃ | ||

A touch probe is a precision tool used in CNC machinesto measure and inspect parts with high accuracy. It operates by making contact with the surface of a workpiece, providing digital feedback to the machine’s control system for automatic measurement or alignment. Touch probes are essential in industries such as manufacturing, automotive, and aerospace for quality control and to ensure parts meet precise specifications. With advanced technology, modern touch probes can offer high-speed, non-contact probing, reducing human error and improving production efficiency. Ideal for automated systems, they enhance precision and reduce downtime.

Their main function is to enhance accuracy and efficiency in manufacturing by enabling automated measurements and adjustments during machining operations.

The probe has a stylus that contacts the part’s surface. When the stylus touches the surface, it triggers a signal indicating the exact point of contact. This information is then sent to the machine’s control system, which records the coordinates of the point. The system uses this data to measure, align, or inspect the part.

Yes, SILVERCNC provides both wired and wireless touch probes, offering flexible options to suit different machining needs and ensure reliable performance.

All products have been sold and used in large quantities, and all recognized by customers

Only 1/2 the price of some well-known brands.

Convenient and cheap to shipping

Hope to be your potential supplier, help to meet your diverse requirement