In the world of modern machining, precision and speed are crucial for maintaining a competitive edge. As industries demand faster production cycles with higher accuracy, the need for innovative technologies has never been greater.

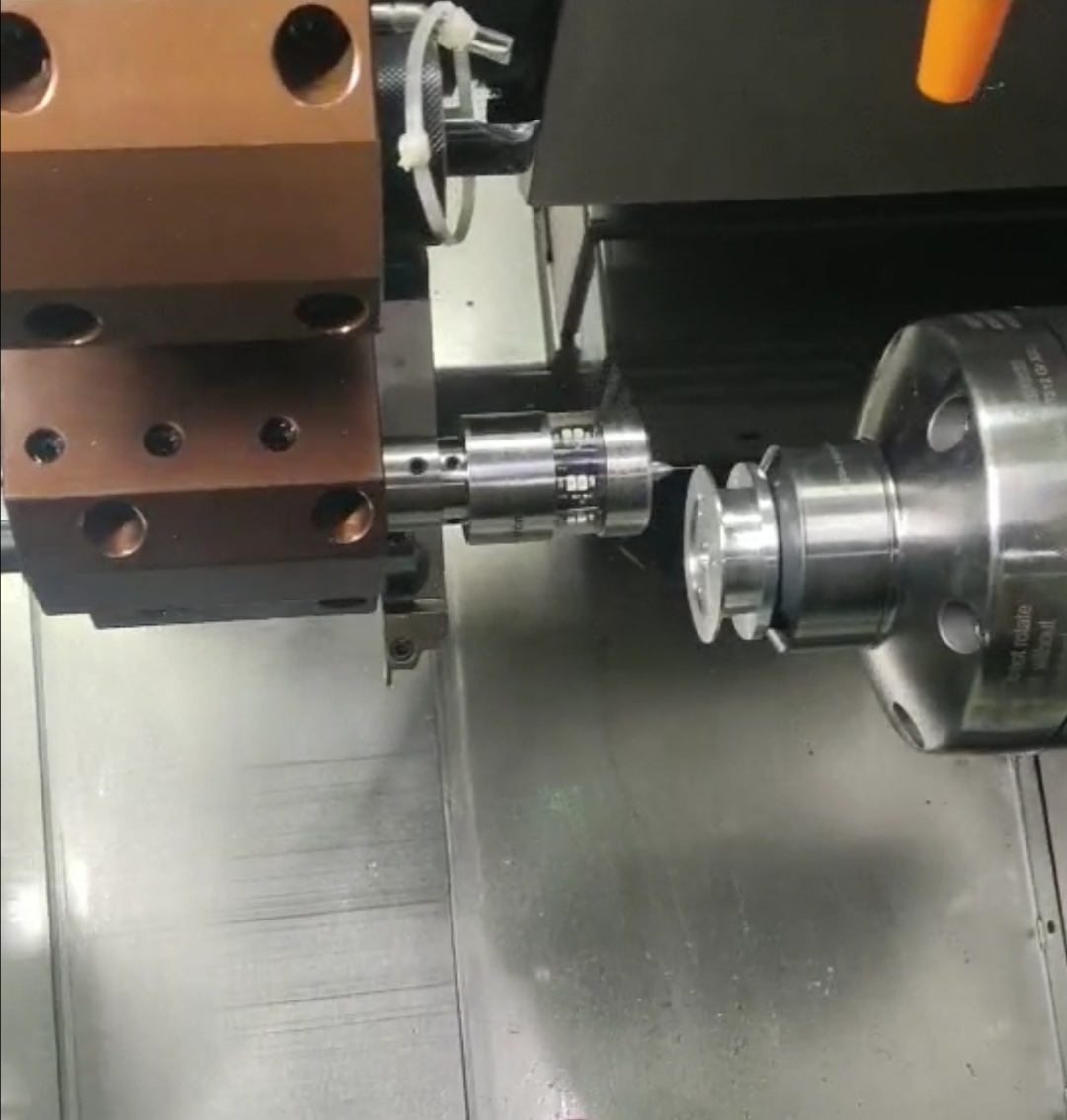

One such technology that has revolutionized manufacturing and machining is the Zero Point Clamping System. This system ensures efficient, repeatable, and high-precision clamping of workpieces, reducing setup times and improving overall production efficiency.

In this guide, we’ll dive into everything you need to know about zero point clamping systems, from their working principle to their applications and advantages.

What is a Zero Point Clamping System?

The zero point clamping system is a unique positioning and locking holding system, ensuring the workpiece or fixture is positioned and locked into a fixed position. Instead of manually measuring and adjusting the position each time a part is installed, the zero point system provide a fast, efficient, and repeatable clamping process.

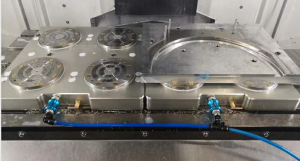

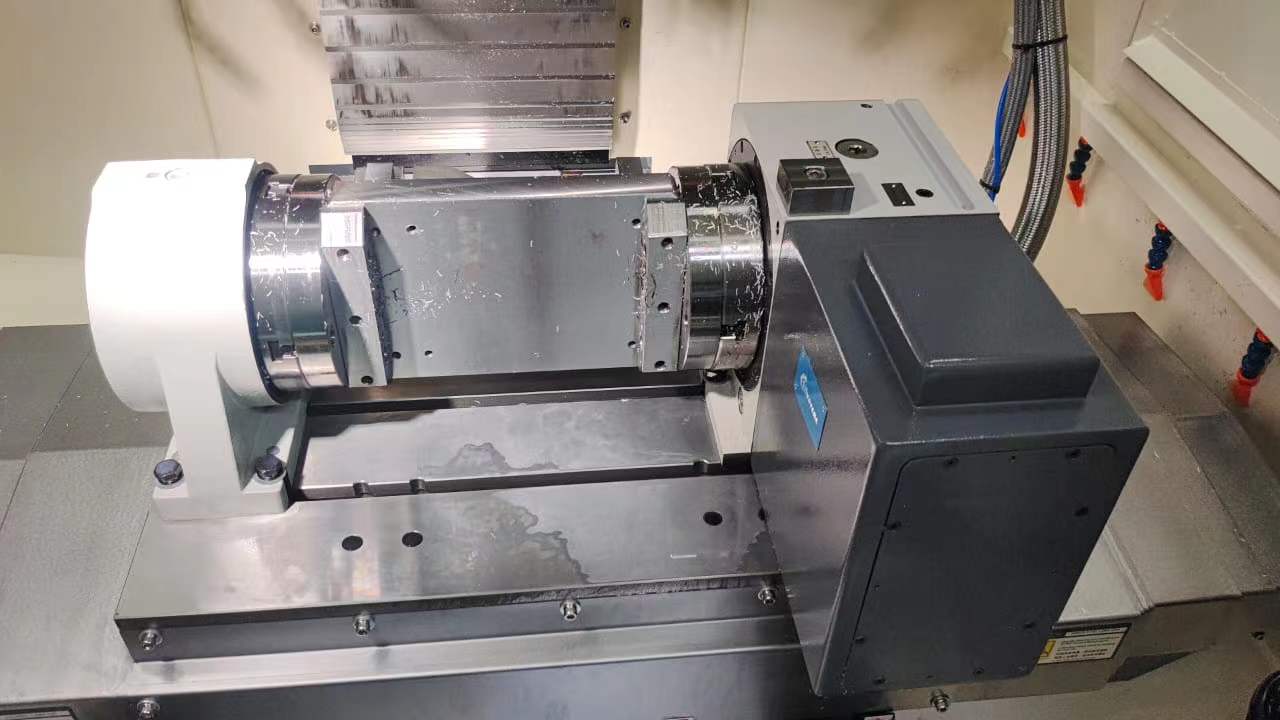

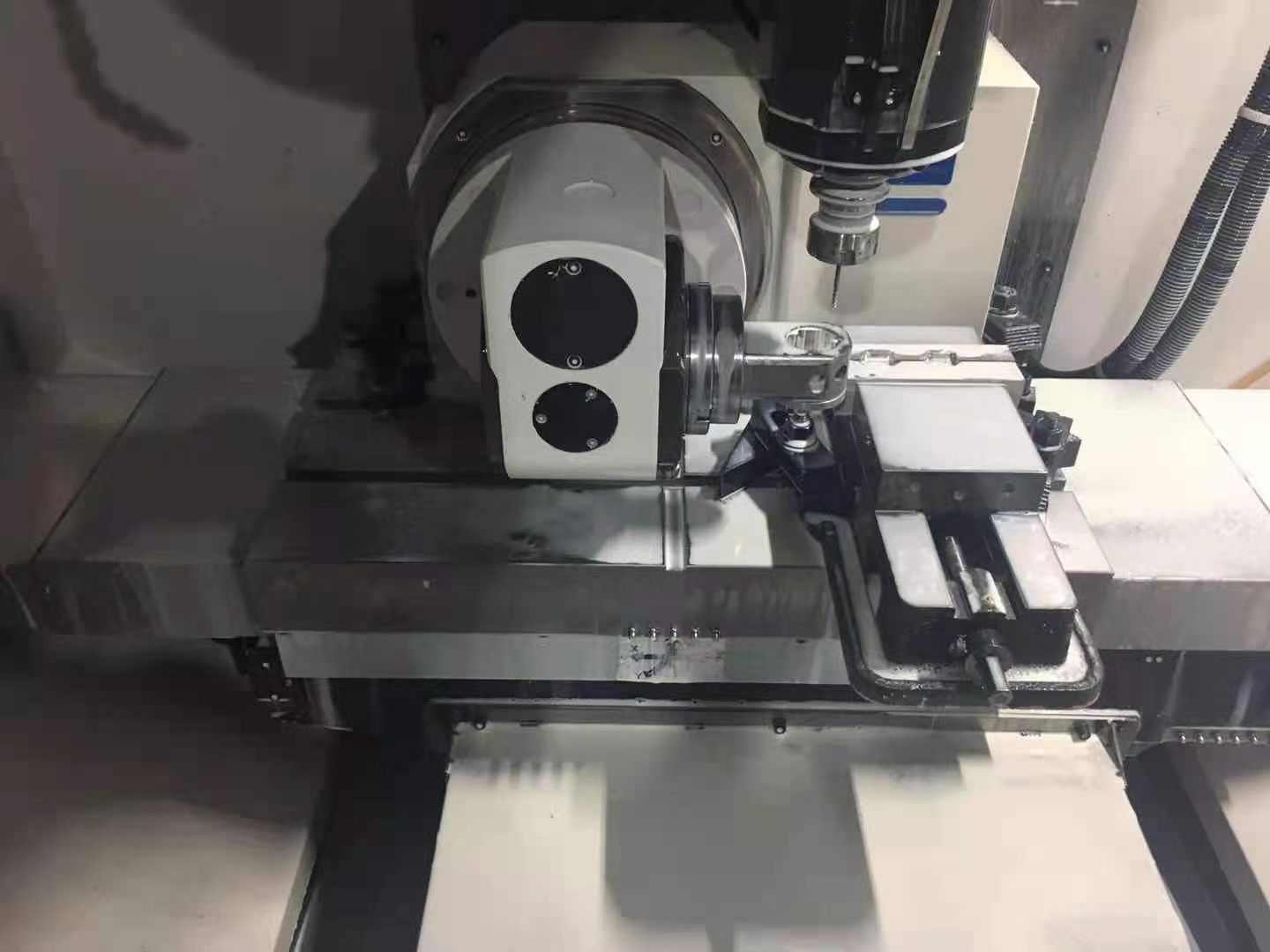

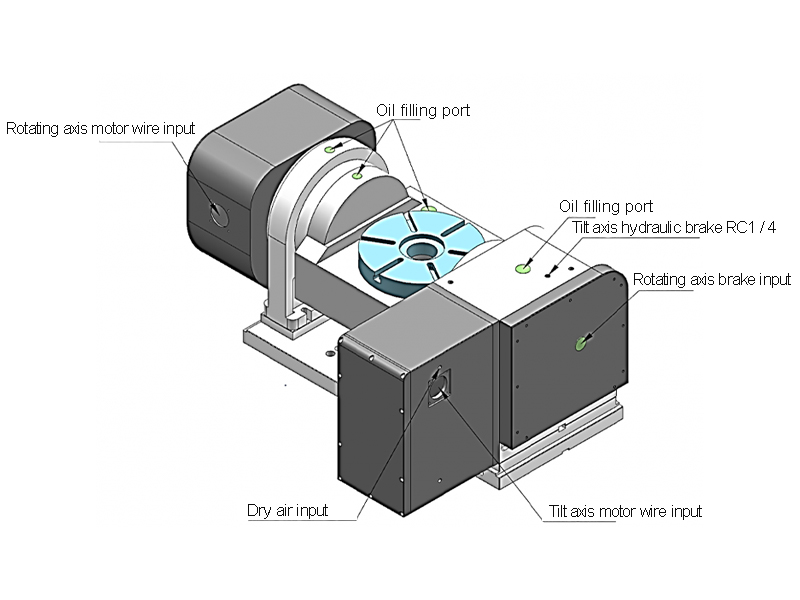

It can keep the fixed reference point remains unchanged from one station to another, from one process to another, or from one machine tool to another. It is widely used in various machine tools such as vertical machining center, horizontal machining center, turn milling compound and so on.

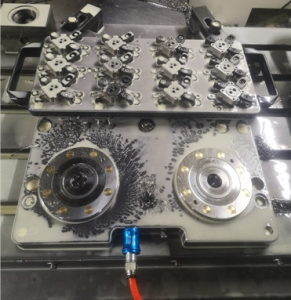

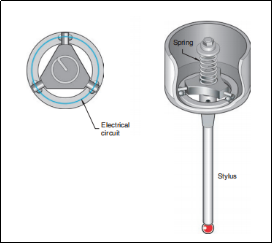

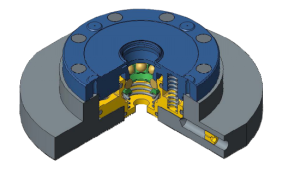

The key clamping device is the zero point plate. This plate has holes where clamping pins are inserted. They are integrated into the workpiece or fixture, requireing high clamping force and repeated positioning accuracy to ensure the interchangeability on different machine tools.

Types of

How Zero Point Clamping System Works?

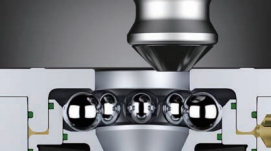

The zero point positioning structure of different brands is slightly different, but the principle is similar. They all adopt hydraulic or pneumatic control mode to clamp or loosen the positioning pin through special mechanical structure.

1. Six point positioning principle

The workpiece has six degrees of freedom in space, that is, the moving degrees of freedom along the three coordinate directions of X, y and Z and the rotating degrees of freedom a, B and C around the three moving axes of X, y and Z. To determine the position of the workpiece in space, six support points, commonly known as positioning elements, need to be arranged according to certain requirements to limit the degree of freedom of the workpiece, which is the “six point positioning principle” of workpiece positioning. It should be pointed out that the shape of the workpiece is different, the positioning surface is different, and the layout of the positioning points is also different.

2. Relationship between restricted degrees of freedom and workpiece machining requirements

According to the different processing requirements of the workpiece processing surface, some degrees of freedom have an impact on the processing requirements, and some degrees of freedom have no impact on the processing requirements. The degrees of freedom that have an impact on the processing requirements must be limited, but the degrees of freedom that do not affect the processing requirements need not be limited.

3. Complete positioning and incomplete positioning

The positioning in which the six degrees of freedom of the workpiece are restricted becomes complete positioning, and the restricted degrees of freedom of the workpiece are less than six, but it does not affect the positioning required by the processing, becoming incomplete positioning. Complete positioning and incomplete positioning are the most commonly used positioning methods of the workpiece in actual processing.

4. Basic principles of workpiece installation

The principle of workpiece installation on NC machine tools is the same as that of ordinary machine tools, and the positioning datum and clamping scheme should also be reasonably selected. In order to improve the efficiency of CNC machine tools, the following points should be paid attention to when determining the positioning datum and clamping scheme:

- Strive to unify the design basis, process basis and programming calculation basis.

- The clamping times shall be reduced as far as possible, and all the surfaces to be processed can be processed after one positioning and clamping as far as possible.

- Avoid using the occupation adjustment scheme to give full play to the efficiency of CNC machine tools.

Benefits of Using Zero-Point System

Time Savings and Increased Productivity

After the zero point clamping system installed and debugged, and the processing program is imported into the machine tool, the workpiece can be processed directly. when changing the fixture, you only need to put the workpiece on the plate of the zero point clamp.

Because the datum point is fixed, there is no need to worry about the change of machining size. It is not necessary to measure while debugging for technicians

Without zero point clamp system, the whole debugging and inspection time is usually more than 30 minutes on average, or even longer. After the zero point system used, the switching time of the fixture can be controlled within 2 minutes, which is equal to more than 28 minutes saved, and the production and processing can be completely carried out. Over the years, the time saved can create higher value.

Consistent Accuracy

After the benchmark is determined, no matter who operates, the accuracy can be kept within 0.005mm. therefore, for the frequent replacement of customers’ on-site operators, it undoubtedly solves the problem of maintaining the stability of product quality.)

Seamless Transition Between Operations

The use of zero point clamping system is very helpful for replacement the fixtures with small batch and multiple varieties product. When the machining of the last batch of parts almost finished, install the part to be planned on the support plate in advance. After the last part completed, removing the fixture, cleaning the table base of the machine tool, putting in the interchangeable support plate, and then calling out the corresponding program to process directly.

Applications of Zero Point Plates

- CNC Machining: Zero point plates are commonly used in CNC machines (3 axis or 5 axis0 to ensure accurate and consistent part positioning for each machining operation.

- Fixture Setup: Zero point plates are used in conjunction with fixtures to enable quick. They are ideal for operations where fast changeover is necessary and where high repeatability is required, ensuring that the workpiece remains accurately positioned between operations.

- Multi-Axis Machines: In multi-axis machines where the workpiece needs to be oriented in multiple positions, zero point plates ensure that the workpiece is accurately clamped in various orientations.

- Tool Changeover: With zero point clamping, tools can be changed quickly while maintaining accurate workpiece alignment, which significantly reduces downtime and enhances productivity.

Zero Point Clamping Device Manufacturer in China Market

There is a huge demand for zero point clamping devices in China’s market., ranking first in the Asia Pacific region and has great growth potential. Therefore, various brands are competing to enter the Chinese market. Here are the players in the Chinese market:

ZEROCLAMP

EROWA

SCHUNK

HAINBUCH

AMF

SYSTEM 3R

LANG

Custom Your Zero Point Clamping System at SILVERCNC

SILVERCNC offers high quality zero point plates and other related accessories such as self-centering vises, 5-axis risers, and clamping pyramids. Made from high-quality alloy steel and treated with surface hardening to 57HRC, our products are highly durable, resistant to scratches, and built to withstand heavy-duty operations. This treatment ensures long-lasting performance and reliability.

We can provide custom options tailored to your specific needs. Available in round, rectangular, and square designs, these systems feature multi-position base plates for flexible workpiece positioning, ensuring compatibility with different setups and machine tools.

Conlusion

Zero point clamping systems are an essential tool for modern CNC machining. They reduce setup time, increase precision, and improve overall machine efficiency. These systems are especially useful in industries where high-volume, high-precision machining is required. With the flexibility, repeatability, and customization they offer, zero point clamping systems are helping manufacturers meet the demands of today’s competitive market. Whether you are working with a 3-axis or 5-axis CNC machine, implementing a zero point clamping system can enhance your production process, reduce downtime, and ensure higher-quality results.